HDPE water supply and drainage pipe extrusion production line

Pipe Production Line Description:

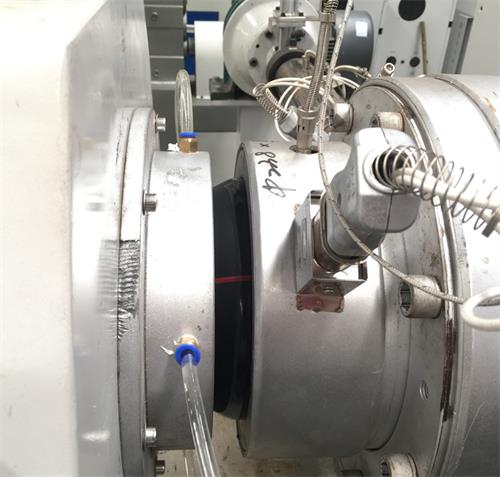

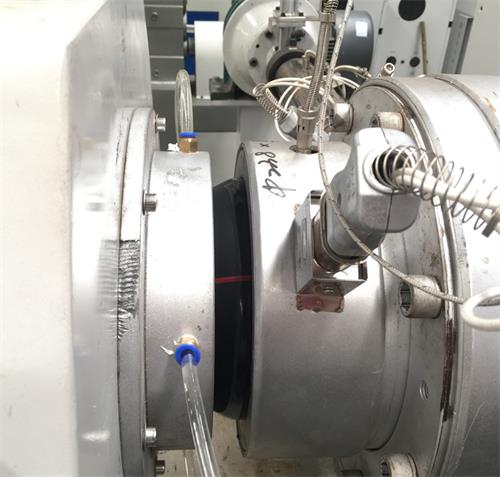

PE pipe production line is developed based on European advanced technology and R&D experience of the plastic machinery for many years. Advanced design, reasonable structure, high reliability, high degree automation of the complete line.

Extruder with special barrel feeding structure can largely improve extrusion capacity.

Accurate temperature control, good plasticization, stable operation.

The complete PE pipe production line adopts PLC control system, realizing synchronization and automation.Human-computer interface is easy to operate, convenient and reliable.Spiral and lattice basket type die head for choice.Dust-free knife cutter and saw cutter for choice.

Changing some parts of the PE pipe production line can also realize two-layer and multi-layer co-extrusion. PE pipe production line can also produce drainage pipe, conduit pipe, PP, PB pipes.

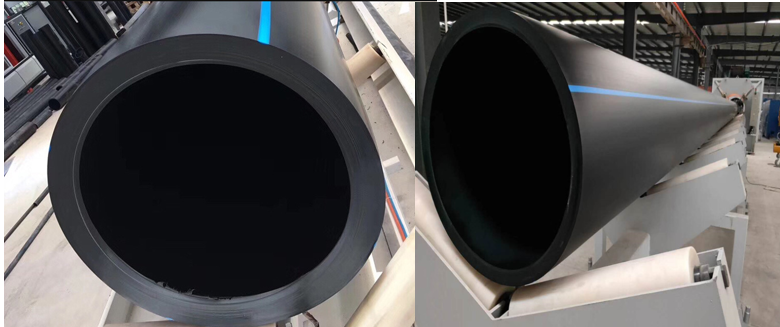

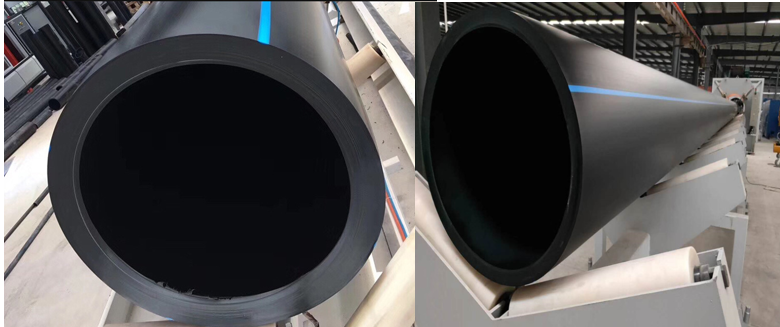

Characteristics of HDPE pipe products

1. UV resistant, aging resistant, life up to 50 years.

2. The inner wall is smooth and the friction resistance is small.

3. The pressure loss is about 30% less than that of steel pipe, so HDPE pipe with smaller diameter can be selected.

4. Good sanitation. There are no additives and no water pollution. PE has strong mildew resistance and can be used for a long time without pollution.

5. PE pipe can be welded into a whole system.

6.Urban water supply system. Large diameter HDPE pipe is healthy and non-toxic, which is more suitable for the use of urban water supply and drainage main pipe and branch pipe.

HDPE pipe production line diameter:

Pipe range

(mm) | 20-63 | 20-110 | 75-250 | 90-315 | 110-450 | 250-630 | 400-800 | 710-1200 | 1000-1600 |

Exturder model | SJ65/33 | SJ65/33 | SJ60/38 | SJ75/38 | SJ/7538 | SJ90/38 | SJ120/38 | SJ90/38 SJ75/38 | SJ90/38 SJ90/38 |

Extruder power

(kw) | 45 | 75 | 110 | 160 | 160 | 280 | 315 | 280 160 | 250 250 |

Max.output (kg/h) | 130 | 220 | 410 | 580 | 580 | 900 | 1150 | 1480 | 1800 |