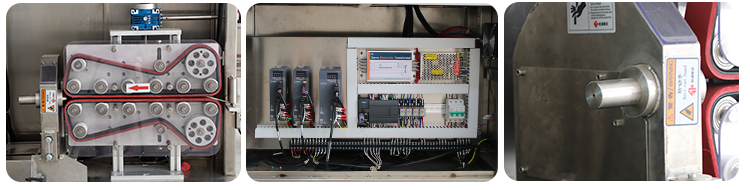

1. PVC screw designed by American technology, with bigger L/D and compression ratio, ensures high speed and stable extrusion, meanwhile provides excellent plasticity. Extruder with “Simens ” A/C frequency motor and high class “Delta” inverter, which provide accuracy and stable output control, Japan “OMRON” PID intelligent temperature controller, accuracy of temperature control: ±1°C;

2. Main body of cooling tank is made from medical standard stainless steel SUS316 material, which can tolerate long-term oxide etch with 10ppm sodium hypochlorite water. Tank frame with spiral elevating device, can be 3-D moved, trouble free operation; Equipped with stainless steel reservoir and medical standard stainless steel centrifugal pump which can form water circulation loop with outside cooling water supply;

3. Adopt England Proton Laser Gauge bi-direction high speed diameter measurement system, which can realize measuring the diameter, ovality and positional value of product on line. Diameter measuring precision can get to ±0.001M

4. Puller adopts imported multilayer composite wearable strap (accord with medical sanitary requirements), with high level precision roller driving, stepless speed control;

5. Cutter equips with low inertia aluminum alloy rotating knife arm structure, together with locking device and alcohol cooling system for cutting knife. Driven and controlled by TECO Servo system, which offers high speed and high accuracy cutting action. With Japan Mitsubishi PLC programmable control and SIEMENS human-computer interface, cutter can realize continuous cutting, timing cutting, length counting cutting etc. Cutting length can be set freely, automatic counting.

CONFIGURATION OF Professional medical management production line:

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| LST series laser diameter gauge | | |

| High speed synchronous belt puller | | |

| Automatic rotary cutting and collecting system | | |