1. Using Taiwan Delta (DELTA) computer control system, with high reliability, fast speed and stability.2. It adopts infrared tube heating, strong penetrating power, heating by the rotation of the preform, orbital revolution and uniform heating.

3. Automatic voltage regulation.

4. The conveyor automatically feeds the blanks.

5. Automatic alarm, automatic fault detection, accurate judgment.

6. Each action is driven by an air cylinder, no oil pump is used, and it has no pollution and low noise.

7. The air circuit is divided into three parts: low pressure action, low pressure pre-blowing and high pressure blowing to meet the needs of different air pressures for blowing actions, to achieve high-pressure blowing finished products and low-pressure stable operation.

8. The unique blowing system is adopted to make the product quality higher.

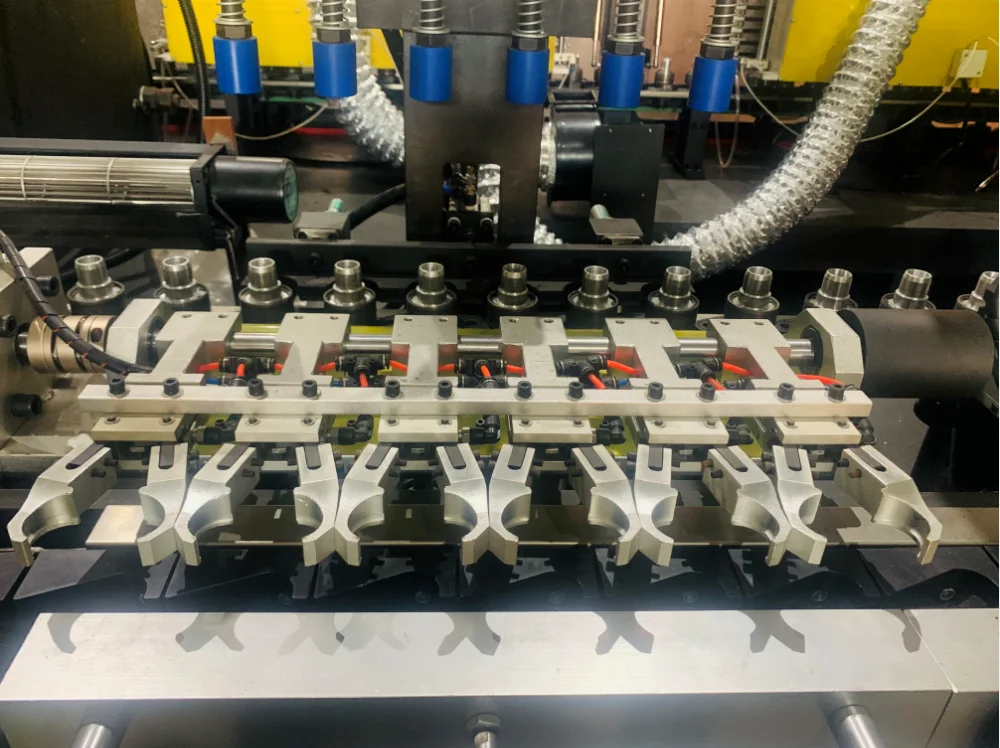

9. Adopting double crankshaft and connecting rod clamping mechanism, strong clamping force, stable and reliable movement.

10. The tie rods made of high-tensile steel and high-quality cast iron templates are used, which are durable and working life.

11. Mould closing moving parts adopt high-rigidity linear guide rail, which is light and fast.