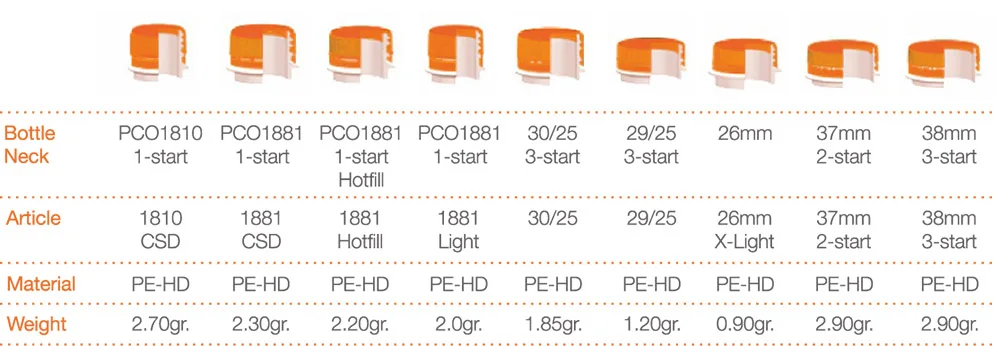

Apply to:water bottle cap,carbonated beverage bottle cap,edible oil bottle cap,medical and medical product bottle cap,cosmetic bottle cap mold design and opening,daily use plastic mold,bottle embryo tube mold,blow mold opening,high speed automatic bottle cap molding machine,bottle cap packaging equipment series machine.

The new generation in series automatic continuous bottle cap molding machine independently developed by our company has international advanced level and has applied for national patent.

The equipment has the advantages of water saving,power saving,environmental protection and low carbon.Compared with the traditional injection molding machine,it has obvious advantages,such as simple operation,convenient maintenance and greatly improved continuous production output.No injection point,make the product more beautiful,saving labor costs.No runner waste,saving raw material cost.Deeply favored by the majority of customers.The product has a wide range of uses,which is suitable for medicine packaging,carbonated beverage packaging,pesticide packaging and other bottle caps.

Cap molding machine is for making caps from plastic materials.The heated materials are extruded from extruder,cutted by segregation plate through screw driving and shared to each cavity equably,then molded to be caps by forming system. The machine is controlled by PLC,including frequency control system,hydraulic system,temperature control system and cooling system.The operating system is easy and automatic with man-machine conversation. As same production capacity,its cost is much lower than produced caps from injection machine.It perfects products with this technology,since there is no gate on cap or no waste of hot runner.