This production line adopts international technology, uses PE, PP, PVC or other plastics compounding with nature fiber powder as the raw material, employs high efficiency conical twin screw extruder ,mould .vacuum calibration table ,tractor and cutter.

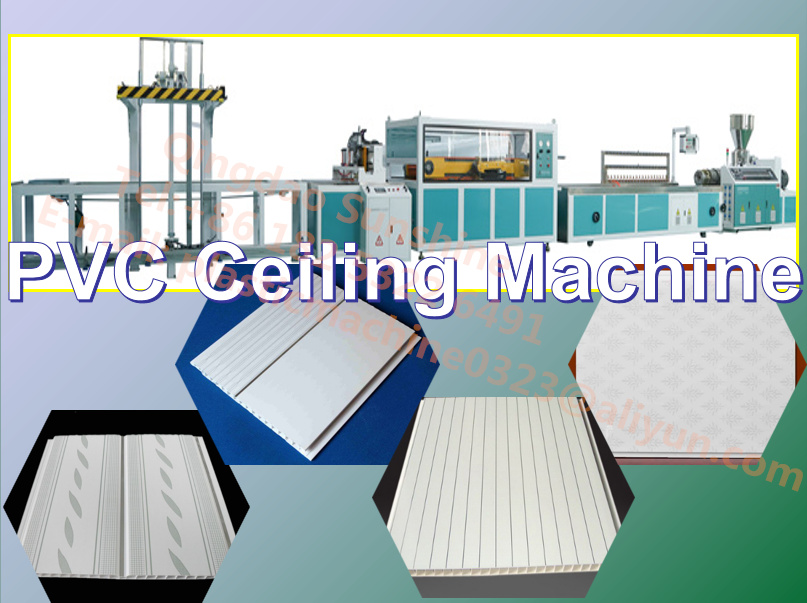

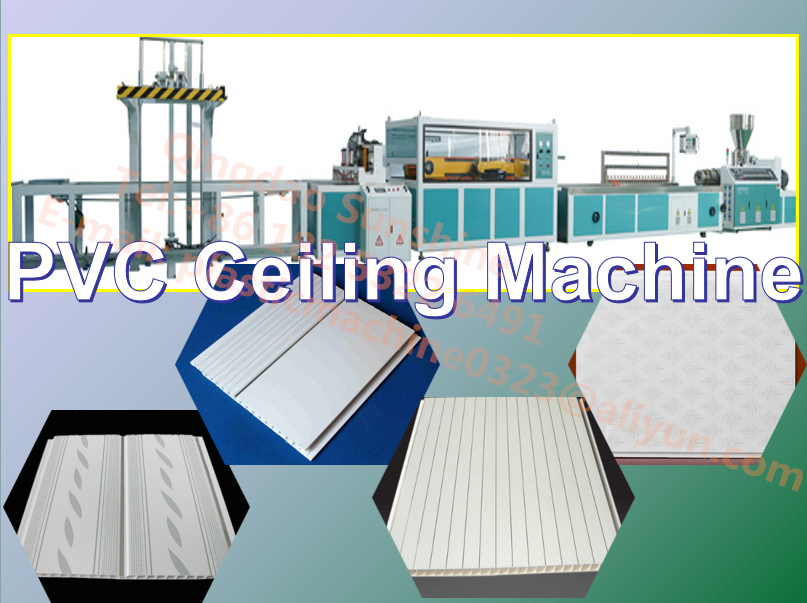

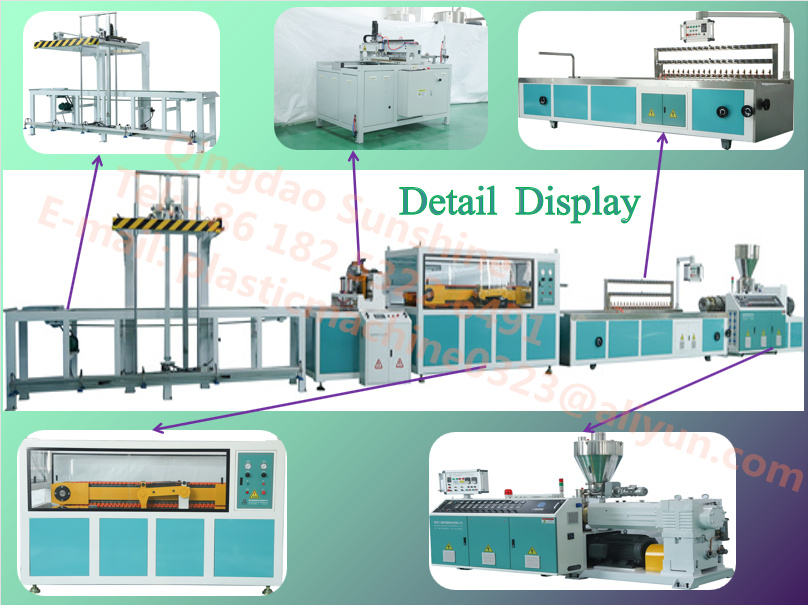

Product Description of PVC Ceiling Board Making Machine/PVC Wall Panel Production Line:

Application:

1.Household ornament: Wall and ceiling of indent independent house bathroom or kitchen;

2.Public and management place: Toilet of building and hall;

3.Common office: Ceiling of business place;

4.More indoor decoration: Hotel, business office, hospital, school, cooking room, washing room and etc.

Technical Parameter:

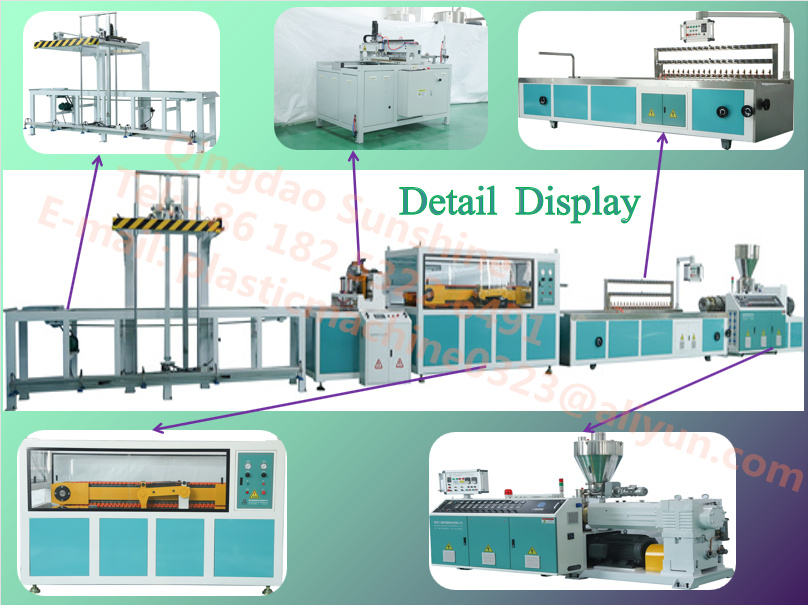

1. PVC PVC Ceiling Board Making Machine/PVC Wall Panel Production Line is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produced all sorts of PVC plastic, profile, plate material, sheet material, bar material and granulation.

2. PVC extrusion for plastic ceiling panel have applied oil cooling system. Barrel is cooled by special wind cooling system.

3. Ceiling Panel and wall panel extruder plant system has applied special computer control. According to customers requirements, most reasonable structure of conical twin screw can be made so as to achieve best plastic city performance and material quality

4. Plastic Extruder machine for Wall panel is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut.

5. The distribution box on Walling Panel making machine is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear large extruding pressure.

6. Plastic extrusion for PVC wall panl and ceiling panel electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1 degree.