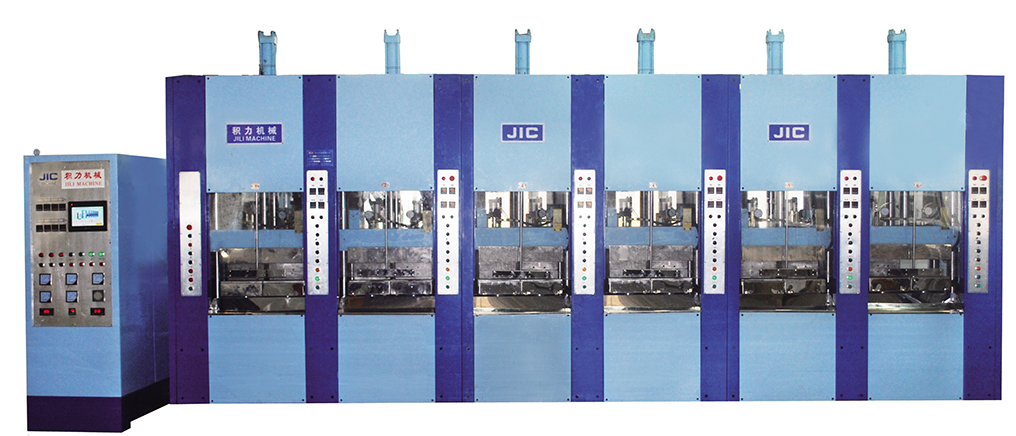

EVA Injection Machine

JIC9106 One Color EVA Injection Molding Machine

Description

one-color injection molding machine for EVA is equipped with two automatic injection units, a highly efficient form clamping system and a PC control system. This machine uses EVA as a raw material for the production of various types of foam EVA products.

Features

1 injection system

This machine provides high accuracy in calculating raw materials, thanks to the PLC and PC control system. The one-color EVA molding machine has linear guides and a drive system that provide high braking speed if necessary, avoiding damage and spoilage of manufactured products. The localization unit provides high precision positioning of the part.

2. mold locking system

The one-color injection molding machine for EVA has a high speed of operation, for which the system for locking and opening the mold is also responsible. This system provides complete tightness inside the mold, for the production of high-quality products. The special design of the machine allows you to fully open the form cover, for ease of use of various forms.

3. control system

One-color injection molding machine for EVA has a convenient working interface with a touch screen, Windows operating system. It provides real-time control, it controls the injection temperature, productivity, drying time. Easy control is provided by PLC and PC.

4. hydraulic system

This machine has a proportional control valve, which provides control of oil flow and pressure.

5. other

This EVA injection machine has a low structure to simplify the control process. The thickness of the molds can be adjusted from 100 to 260 mm. This allows you to work not only with EVA, but also with rubber. Benefits

1. The mold locking system of this EVA injection molding machine has a fast and efficient locking system thanks to the hydro-pneumatic drive. 4 oil cylinders of this machine provide high working pressure up to 200 tons.

2. Thanks to the network monitoring system, this one-color EVA injection molding machine can be controlled from a distance. Thanks to the industrial PC and PLC, all performance and indicators are displayed on the screen and can be adjusted.

3. High-precision proportional control valve ensures smooth operation of the injection system. The fuel pump for the injection system has a high accuracy of up to 2 ‰ ±, which guarantees high quality and efficiency.

4. This machine has an anti-blocking system, temperature control system accurate to one degree, this system does not allow product deformation due to temperature changes.

5. Each workstation has two modules that work independently with each individual form, which allows you to increase productivity and efficiency.

Parameters:

Project | Unit | Specifications |

Model |

| 9102 | 9106 | 9108 |

Raw Material |

| EVA | EVA | EVA |

Work station number(max) | station | 2 | 6 | 8 |

Clamping force | T | 180 | 180 | 180 |

Mould-opening Stroke | mm | 350 | 350 | 350 |

Max Mould Size | mm | 290*550 | 290*550 | 290*550 |

Mould Height | mm | 100-200 | 100-200 | 100-200 |

Screw Diameter | mm | ¢60 | ¢60*2 | ¢60*2 |

Screw Speed | rpm | 0-165 | 0-165 | 0-165 |

Injection capacity(max) | cm3/cc | 930 | 930*2 | 930*2 |

Injection Pressure | kg/c㎡ | 1080 | 1080 | 1080 |

Limit of temperature | point | 4 | 4 | 4 |

Barrel Heat Power | kw | 6 | 6*2 | 6*2 |

Mould Heat Power | kw | 25.6 | 76.8 | 102.4 |

Hydraulic Motor Power | kw | 37/32 | 55/50 | 55/50 |

Total Power | kw | 62/57 | 131/126 | 157/152 |

Oil Tank Size | kg | 800 | 1000 | 1000 |

Machine Size | mm | 4680*4600*2875 | 8230*3800*2875 | 10650*4800*2875 |

Machine weight | kg | 11000 | 26000 | 33000 |

One-color EVA Parts Injection Molding Machine and Disc Feeder from Jili Co. work depending on pressure level. The disk feeder has various operating modes, calculated for various raw materials, all parameters can be set through the control panel. Linear guides provide quick movement of injection blocks during operation.