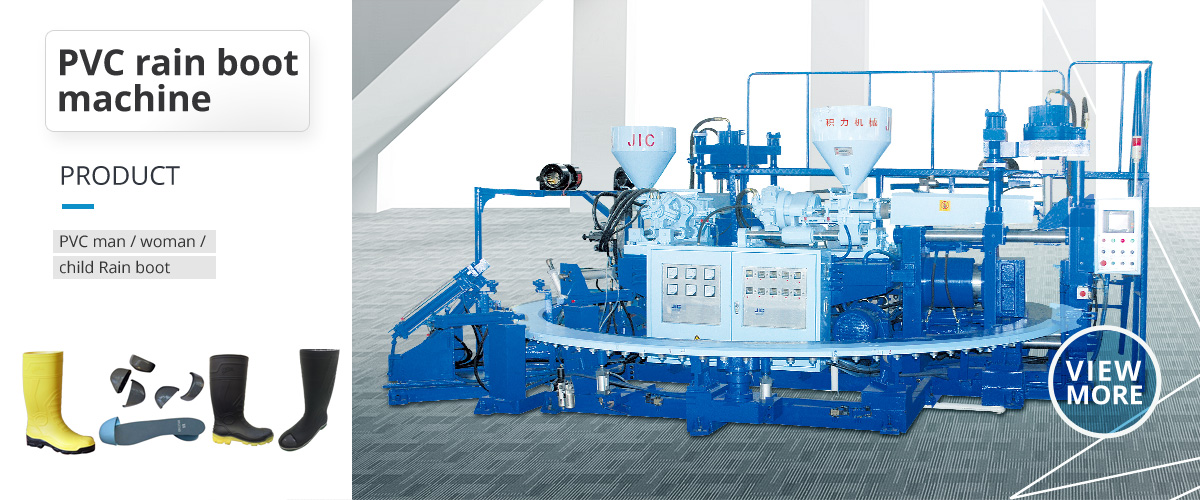

JIC724A PVC Air Blowing Molding Machine

Properties

1. The products of the blow injection machine are soft and comfortable. Compared to a traditional machine, this machine can reduce the weight of its products by 20-30%

2. The mixture of old and new material is applicable to our injection machine, and its products are of the same quality as those with new material.

3. The cooperation between the control of the pressure of the oil, electrical appliances, machinery and the pneumatic system achieves a wide production, with less energy and less work.

4. The exact design of the machine helps accommodate large molds. Our air blown PVC shoe injection machine has a cooling system that increases the quality of the shoes produced.

5. All operations are controlled by a control panel with human-computer interaction interface, in addition to the process being precise and easy handling.

6. There are protection switches to ensure the protection of the manipulator and the machine.

Features

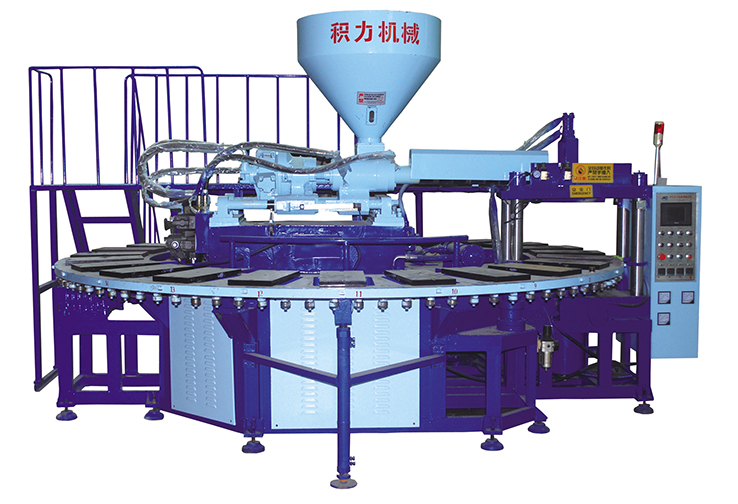

1. The PVC injection shoe blowing machine has a double proportion hydraulic system, which increases functionality and stability. High quality of the products is obtained by co-monitoring the pressure injection and the injection flow.

2. The machine process is fully automatic. With modern automatic expansion equipment, work is saved and the operation is more precise.

3. The blow injection machine is used in the production of all kinds of PVC shoes such as sandals, slippers and PVC soles.

4. A circulatory cooling system is used to increase the cooling capacity and production quality.

5. All professional operations such as injection, material supply, disc rotation, clamping, etc. They are programmed by the control system. All parties can be coordinated.

Parameters:

Project | Unit | Specifications |

Model |

| 724A |

Work station number(max) | station | 24 |

Injection capacity(max) | cm3/cc | 770 |

Injection Hydraulic | kg/c㎡ | 0-120 |

Heating Power | kw | 13 |

Limit of temperature | point | 4 |

Screw Speed | r.p.m | 0-150 |

Screw Diameter | mm | ¢70 |

Motor Power | kw | 18.5 |

Clamping force | T | 60 |

Mold Size L*W*H(max) | mm | 460*220*240 |

Mould Height | mm | 80-240 |

Machine Size | mm | 4460*4050*2300 |

Gross Weight | kg | 6000 |