Home > Product

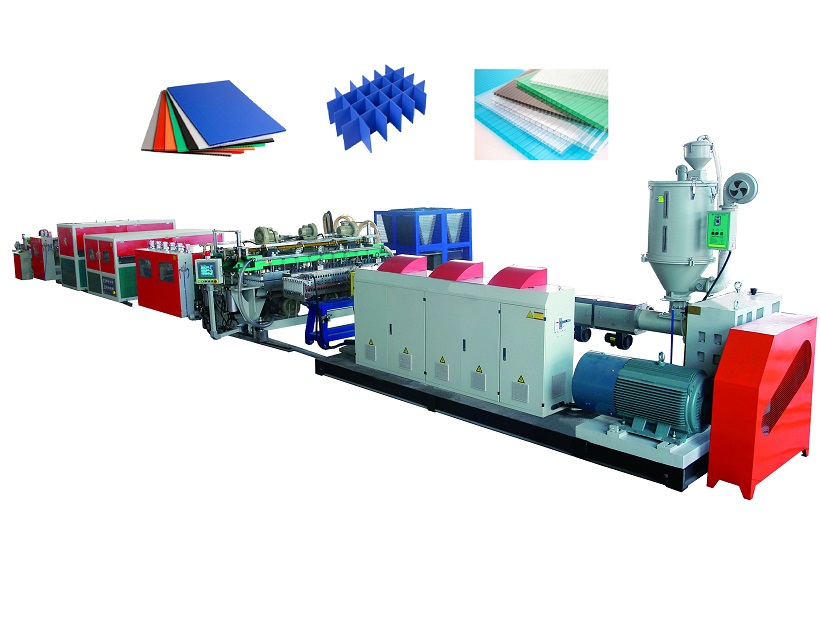

Categories > PP plastic corrugated corflute sheets making machine for floor covering sheet

PP plastic corrugated corflute sheets making machine for floor covering sheet 670 Favorites

| Product Categories: PC/PP/PE Hollow Sheet Machine | |

| Packaging Details:Standard packing requirement, | Trademark:SJR |

| Certification: CE, ISO9001:2008, | |

| Payment Terms: L/C, T/T, | |

| FOB: USD $135000/Set | HS Code: |

| Loading Port:Qingdao port | |

| QingDao SJR Machinery Co., Ltd. | |

|---|---|

| Company type: Manufacturer | Credit:

|

| Main products:Plastic machine,plastic products,spare parts and other machine | |

Contact Supplier

Reminding

Message has been sent successfully.