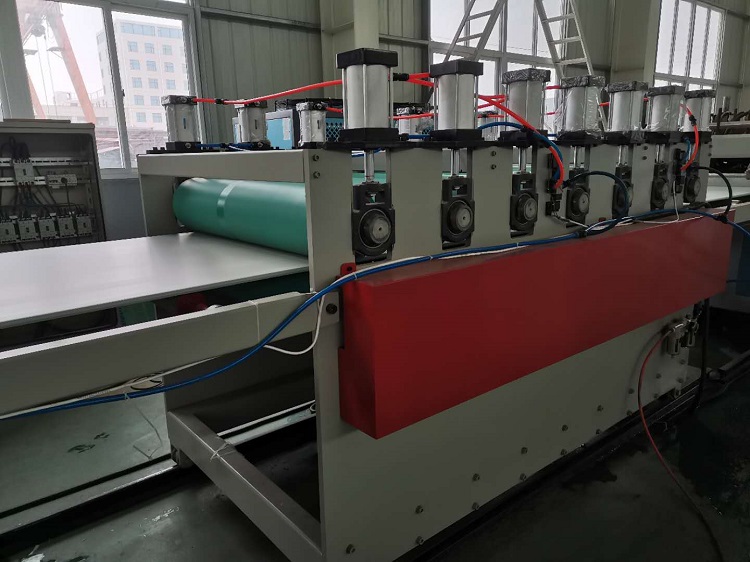

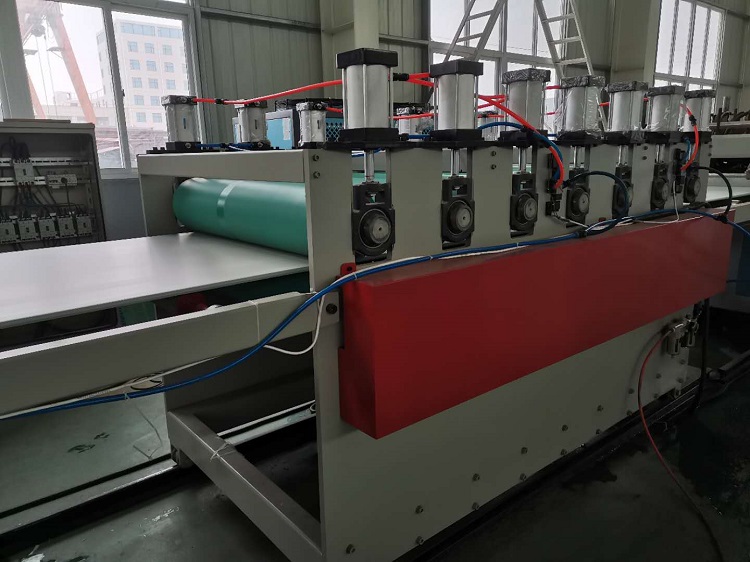

PP Hollow Building Template Board Production Line

The PP building templates extrusion production line is successfully developed by our company to absorb and digest foreign advanced extrusion technology and independent innovation. The plate thickness range can be made to 8-18mm, and the plate width can be customized according to customer's requirements of 600mm-915mm-1220mm. Its production surface is smooth and clean, Small size error, with nail, planing, corrosion resistance, flame retardant and many other advantages.

This unit is the special equipment for extruding PP/PE hollow grid board directly. The grid boards have the strong point of smooth and clean surface, good outlook and pressure resistance. It can be widely used in construction, package and adornment industries.

The production line can produce PC hollow grid board, also named sunshine board, mainly applied for agriculture and construction transparent warm keeping, just need to change the die mold.

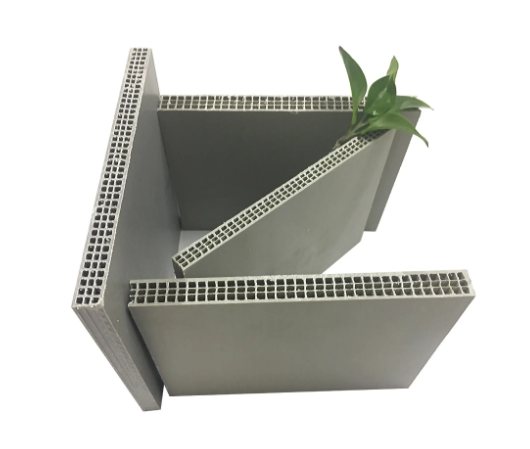

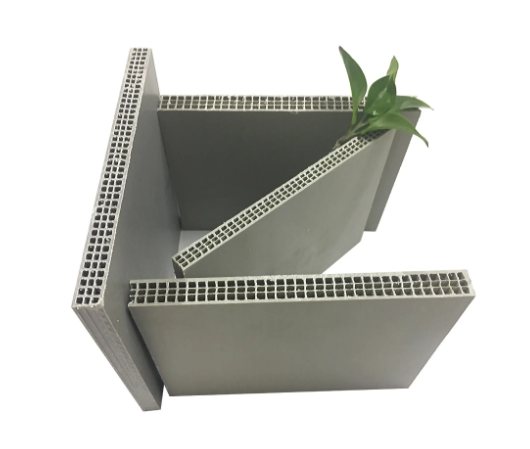

Advantages and features of hollow formwork:

1. Smooth and clean.The splicing of the formwork is strict and smooth, and the surface degree and finish of the concrete structure after demoulding exceed the technical requirements of the existing clear water formwork.

2. Portable and easy to install.Light weight, strong process adaptability, can saw, planer, drill, nail, can be composed of any geometric shape, to meet the needs of various shapes of building die.

3. Simple stripping.Concrete does not stick to the surface, no need of demoulding agent, easy demoulding, easy to remove ash.

4.Specification : 915MM*1830MM,1220MM*2440MM

5. Plastic formwork has the characteristics of moisture resistance, corrosion resistance, acid resistance and alkali resistance, especially suitable for underground and humid environment.

6. The plastic formwork has the advantages of high strength, toughness, impact resistance, strong elasticity, and is not easy to deform, thus greatly improving the turnover of formwork.

7. Plastic formwork can be used together with wood (bamboo) plywood and other materials.

8. The waste formwork can be recovered and replaced with the old one, which can save more cost and is beneficial to the development of formwork leasing industry.