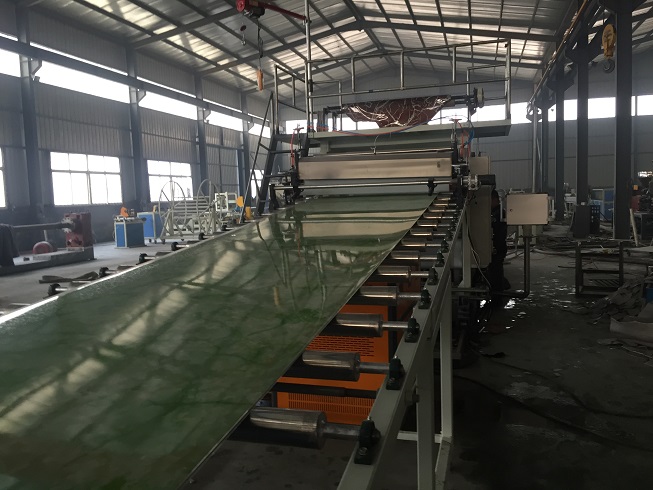

PVC crust foam board extrusion line

Features:

1>Strong and durable; Lightweight and easy to install; Not easy to scratch;

Will not rot, warp, delaminate, cup or twist;

2>Resistant to weather, shock and abrasion;

3>Salt water corrosion resistant;

Impervious to salts, insects and many chemicals, including some acids;

4>Doesn't mold; Can be worked just like wood;

Non-toxic; 100% recyclable; Fire-retardant (self-extinguishing);

5>Easy to clean; Virtually maintenance free;

Extrusion line details:

1. SJSZ 80/156 Conical twin Screw Extruder

ABB frequency converter, Siemens contactor, OMRON Japan, Motor power: 75KW

2. Calibration unit

Calibration plate: 1500mm× 500mm 4 couples

3. Cooling tank and bracket length: 6000mm trimming knife: 3 sets

4. Haul-off unit

8 couples cylinder clamping and loosening

5. Cutting unit

6. Stacker

7. Mould (T-Die )

PVC crust foam boards are mainly used as high-end and environment-friendly products, such as high-class furniture, high-class bathroom cabinet and advertisement board, PVC crust foam boards are well-known adopted in star-level hotel and luxury sites, which medium density fiber panel can not be compared with.

If you want more details about this PVC crust foam board production line. Please contact us.