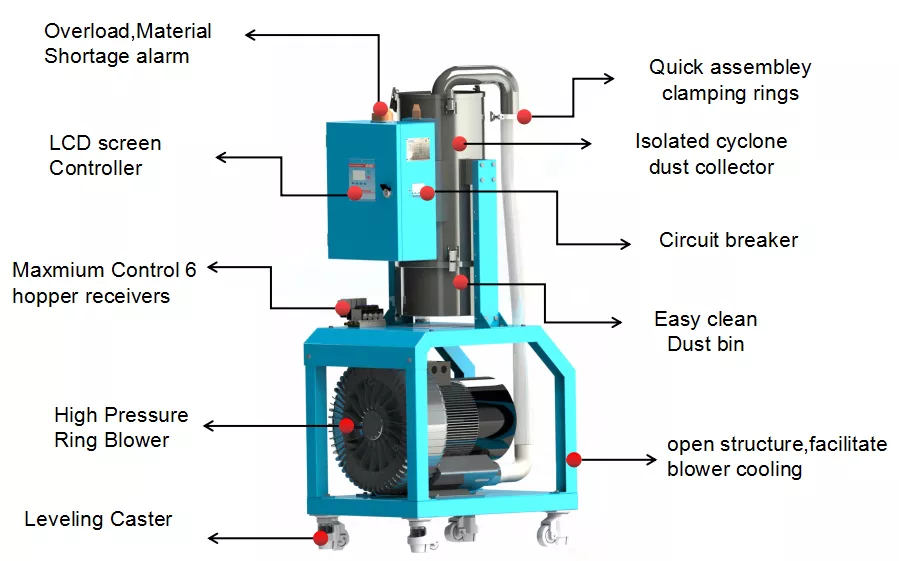

Full automatic programmed operation.

Automatic alarm for overload or short of material.

Stainless steel hopper construction.

Main controller and hopper designed separated, to ensure safety and convenient.

Separated filter installation, easy to remove pooling of powder.

Automatic reverse to clean filter.

Maximum 6 feeding station available.

Product Specification

| |

| | | | | |

| |

| |

Motor Power(KW) | | | | | | |

Conveying Capacity(kg/hr) | | | | | | |

Loading Height(m) | | | | | | |

| | | -------------------------------------- |

Dimensions(mm) | | | | | | |

| | | | | | |

Customer Cases

Company Profile

Dongguan Mitex Automation Machinery Co.,ltd.

In July 2007, China Dongguan Mitex Machinery Technology Co., Ltd. was established.

Dongguan Mitex Machinery Technology Co., Ltd. is a manufacturer specializing in planning the peripheral auxiliary system of plastic molding automation in the whole plant. The main products include: centralized feeding system, dehumidifying and drying system, automatic metering and mixing system, crushing and recycling system, mold temperature control system and so on. It has been widely used in injection molding, extrusion, blow molding, die casting and other fields.Mitex will focus more on meeting the needs of customers and provide the most advanced and effective molding peripheral auxiliary systems and services. Save costs and create value for customers and share brilliant results together!

Contact Details