Home > Product

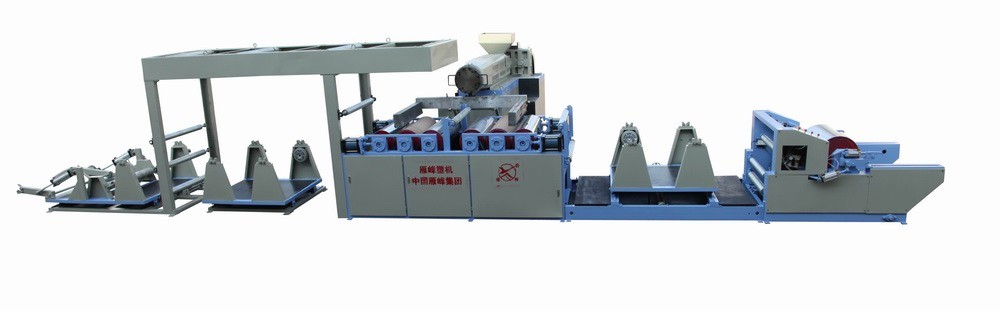

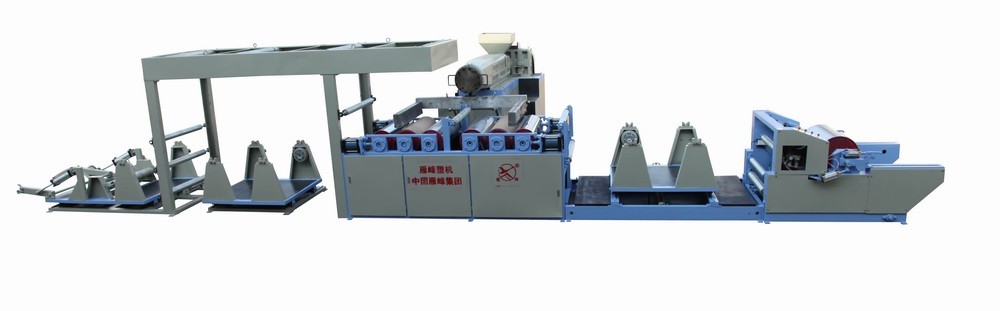

Categories > Factory Manufacturer Multifunctional Lamination Machine Coating Machine for PP Woven/Sack Animal Feed Bag

Factory Manufacturer Multifunctional Lamination Machine Coating Machine for PP Woven/Sack Animal Feed Bag 880 Favorites

| Product Categories: Coating Machine | |

| Packaging Details:By sea | Trademark:Yanfeng |

| Certification: CE, ISO9001:2008, | |

| Payment Terms: L/C, T/T, | |

| FOB: USD $39500/set | HS Code: |

| Loading Port:Wenzhou | |

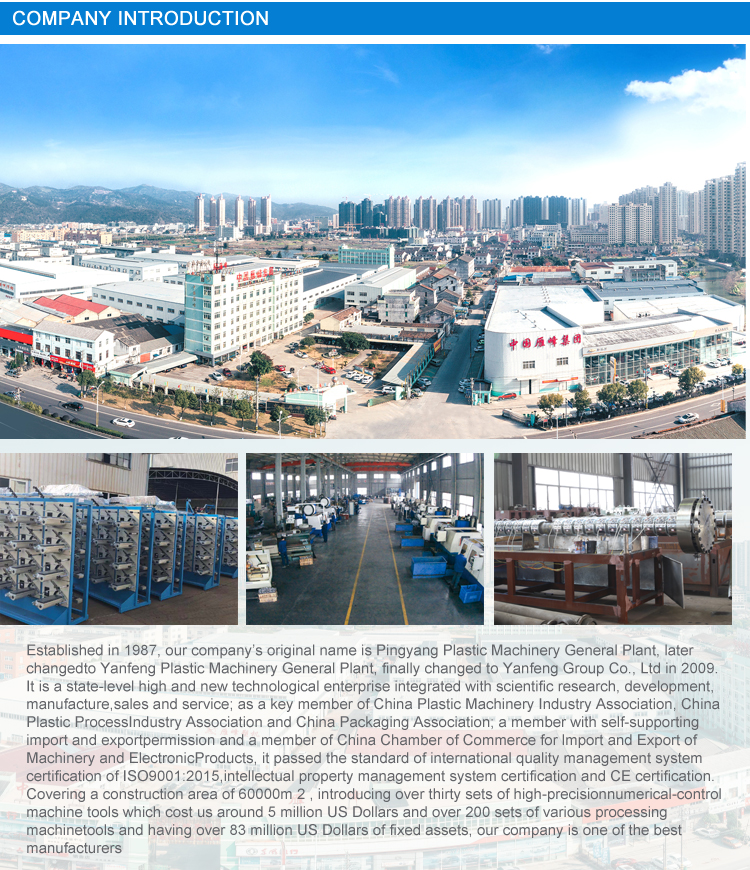

| Yanfeng Group Co., Ltd | |

|---|---|

| Company type: Manufacturer | Credit:

|

| Main products: | |

Contact Supplier

Reminding

Message has been sent successfully.