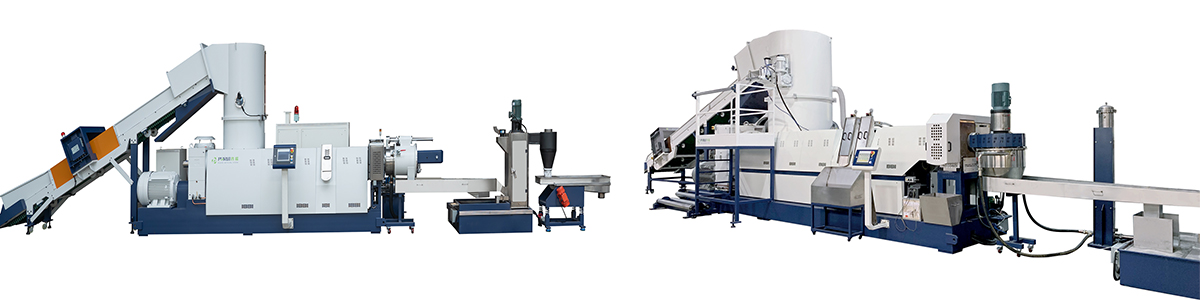

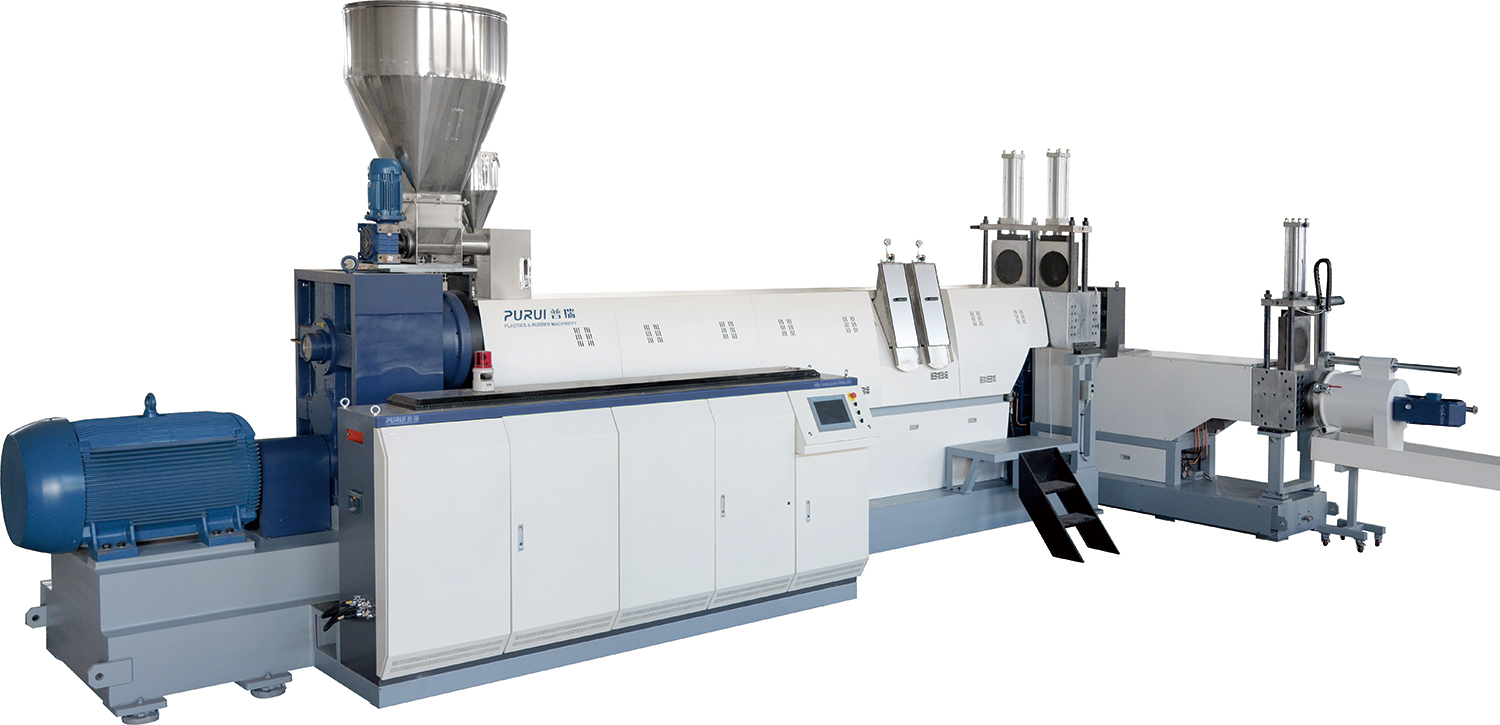

SJ type granulator for PP and PE rigid/hard scraps plastics and squeezed plastics after plastic squeezer. It performs well in recycling the HDPE bottle flakes from the detergent bottles, HDPE milk bottles, etc.

Two times filtering will guarantee the pellets quality. The filtering mesh size the first stage can use 60mesh. The second stage filtering mesh will be 80-100mesh.

2.Great vacuum degassing system. We use the watering vacuum pump in the pelletizing line. The exhausted gas extract from the extruder and goes into water cylinder for filtering.

3.The screw design is specialized to specific materials.

4.The heaters we used in the barrel is best and reliable in China with long service time.

5.Pelletizing method is optional. The watering pelletizing is suitable for PP and PE films, while for the strand pelletizing it can be used in PP PE and PC and ABS and PA. Also the underwater pelletizing will be universal. All pelletizing method will be easy to maintain and long service time.

6.Good motor brands and qualified high torque gearbox. We use the China best brand motors, Dazhong,and the WEG with UL certification, ABB motors, and Siemens motors optional. Electric parts use the the international brand Schneider or Siemens. Temperature control OMRON. Siemens PLC control is available. Good electric protection method in the machine.

7.Nice design for the safety and usage in plant. We have strict quality control.