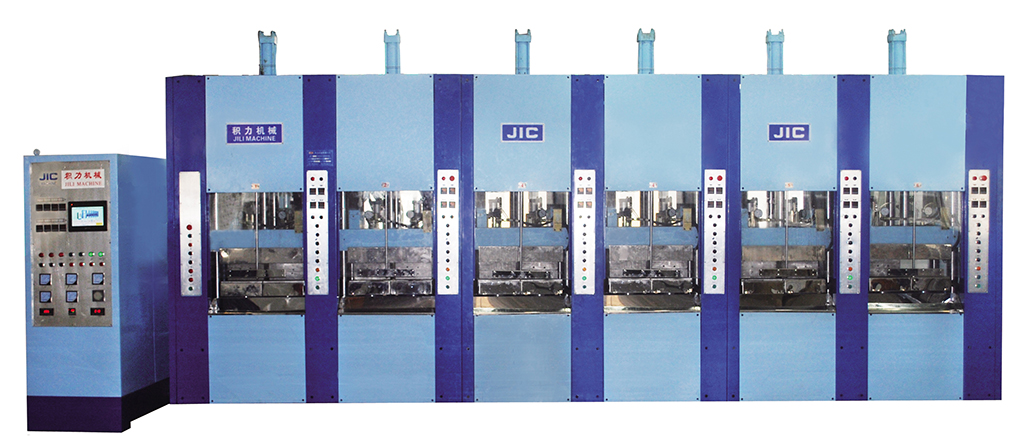

1. Injection system

The measuring mechanism utilizes potentiometer detection and coordinates with PLC and PC calculation to accurately control the quantity of material. The injection seat shifting mechanism is driven by linear slide rail with reducer, and the high-speed displacement is controlled by frequency converter. The positioning mechanism uses rotary encoder to accurately detect the position.

2. Mold clamping system

The two - stage fast opening and closing mold mechanism with fully closed mold detection device. Low operating platform and higher mould stroke can be apply to various style of molds flexibly.

3. Control system

Windows operating system to build the control program, using image man-machine interface, with touch screen which can online monitoring feed speed, injection quantity, injection time, injection temperature, sulfur time and output, easy to learn and operate. PLC module system design, each function structure is clear;

4. Hydraulic system

Adopt double proportional control valve to coordinate with computer control system can accurately control the multi-section pressure and flow;

5. Energy-saving design mold station heat insulation board free of water, using high efficiency heat insulation material;

6. Low operating platform accord with ergonomics;

7. The mould height can be adjusted step-less and suitable for 100-260mm mould gap.

项目 Project | 单位 Unit | 规格 Specification |

型号 Model |

| 9102 | 9106 | 9108 |

原材料 Raw Material |

| EVA | EVA | EVA |

工作站数 Work Station Number(max) | station | 2 | 6 | 8 |

锁模力 Clamping Force | T | 180 | 180 | 180 |

开模行程 Mould-opening Stroke | mm | 350 | 350 | 350 |

模具尺寸 Max Mould Size | mm | 290*550 | 290*550 | 290*550 |

容模高度 Mould Height | mm | 100-200 | 100-200 | 100-200 |

螺杆直径 Screw Diameter | mm | ¢65 | ¢65*2 | ¢65*2 |

螺杆转数 Screw Speed | rpm | 0-165 | 0-165 | 0-165 |

最大射出容量 Injection Capacity(max) | cm³/cc | 930 | 930*2 | 930*2 |

射出压力 Injection Pressure | kg/cm² | 1080 | 1080 | 1080 |

温控段数 Limit of Temperature | point | 4 | 4 | 4 |

料管加热功率 Barrel Heat Power | kw | 6 | 6*2 | 6*2 |

模具加热功率 Mould Heat Power | kw | 25.6 | 76.8 | 102.4 |

油压系统马达 Hydraulic Motor Power | kw | 37 | 50 | 55 |

总功率 Total Power | kw | 62 | 131 | 157 |

用油量 Oil Tank Size | kg | 800 | 1000 | 1000 |

机械尺寸 Machine Size | mm | 4680*4600*2875 | 8230*3800*2875 | 10650*4800*2875 |

机械重量 Machine Weight | kg | 11000 | 26000 | 33000 |