The unit takes custom-designed conical twin-screw extruder to make use of a great deal of wood flour and fibers.

It adopts imported transducer and temperature-control system to control temperature, which precision of temperature-control can reach ±1℃. Auxiliary machine consists of vacuum shaping table, tractor, cutter and stacker. The unit is equipped with large scaled cooling device to guarantee the effects of shaping. The caterpillar tractor using imported transducer to regulate speed has merits of proper construction, great traction force and stable traction. The cutter adopts transverse cutting type, which contains imported electrical components and pneumatic components, has stable accuracy for cutting.

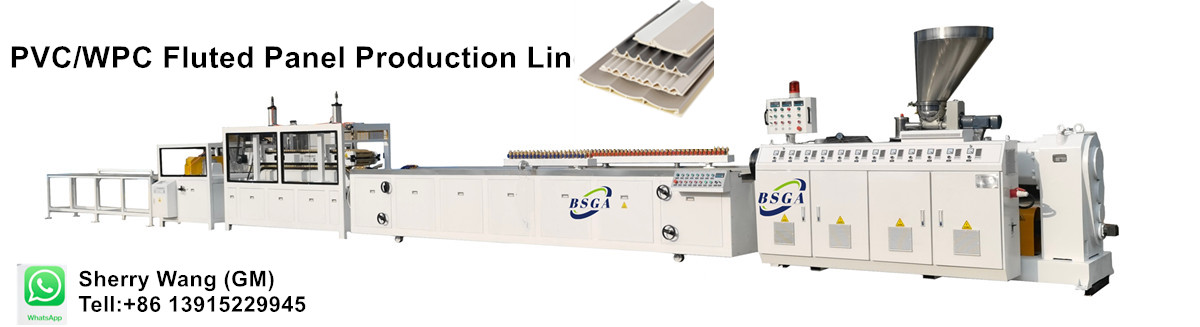

It can produce PVC shaping board, door board, windowsill, wood plastic foaming sheet etc.

Main Technical Parameter of Auxiliary

生产线型号Model | YF600 | YF800 | YF1000 | YF1500 |

最大型材宽度Max. product width(mm) | 600 | 800 | 1000 | 1500 |

真空定型台长度Vacuum shaping length(mm) | 6 | 6 | 6 | 6 |

牵引速度Draw speed(m/min) | 0-5 | 0-5 | 0-5 | 0-5 |

锯片直径Cutting saw Dia. (mm) | Φ400 | Φ400 | Φ400 | Φ400 |

辅机总功率Total power(kw) | 31 | 33 | 38 | 48 |

整条生产线长Length of line(m) | 23 | 28 | 30 | 35 |

整条生产线宽度width of line(m) | 1.4 | 1.6 | 2 | 3 |