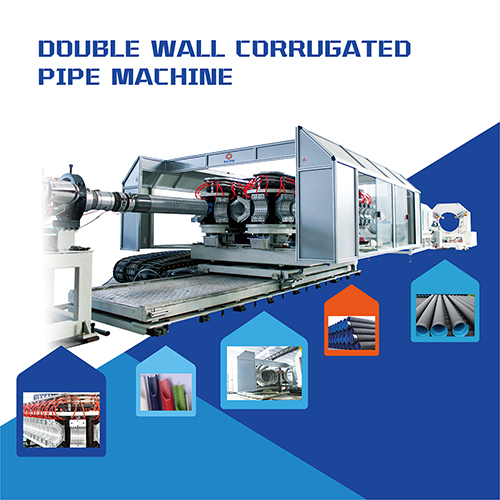

Double Wall Corrugated Pipe Machine

The double-wall corrugated production line is developed and manufactured by Yasense which is designed by using the template of the forming machine,

and the products are water cooled through the gear drive module, so that the forming speed quickly, with uniform corrugated shape, consistent joints,

and smooth inner and outer walls.

Main Features:

1. Suitable to produce PE, HDPE, LDPE pipe extrusion.

2. Raw Material: PE HDPE granule.

3. Capacity: 3-6m/min.

4. Mainly includes: vacuum drying auto feeder, Single Screw Extruder, die head, Core bar and mouth mold, Pipe Forming Machine, Winder.

5. Supply technical service, formula guide and staple raw material purchase.

Our Advantages:

1. Optimized screw and newly designed slotted sleeve, higher fusion rate, even melting, and stable continuous production.

2. The high-efficiency gear motor provides greater torque, longer service life, and lower noise.

Main Technique Parameter:

|

Model

|

YS110

|

YS160

|

|

Pipe diameter (mm)

|

DN/ID 40-110mm

|

DN/ID 110-160mm

|

|

Extruder

|

SJ75/30+SJ65/30

|

SJ90/30+SJ65/30

|

|

Die head, Forming mould

|

40-110mm

|

110-160mm

|

Note: Informations listed above are for reference only, the production line can be designed by customer’s requirements.