Lab extruder is specially designed for the trial-level or entry-level user, or the small scale production of color masterbatch and some additive masterbatch. Modular design makes it very flexible against different recipes

Application of lab extruder

Applications of our lab extruder include compounding, direct extrusion, degassing (devolatilization) and reaction extrusion.

They can be used to stimulate the continuous extrusion process for batch samples, new material research, new process development and small quantity production.

Technical data of lab extruder:

|

Mode

|

Diameter

(mm)

|

L/D

|

Screw rotary speed

(r/min)

|

Motor power

(kw)

|

Capacity

(kg/h)

|

|

TSE-20

|

22

|

32-48

|

600

|

5.5

|

5-10

|

|

TSE-30

|

31

|

32-48

|

600

|

15

|

10-40

|

|

TSE-40

|

41

|

32-52

|

600

|

15

|

65-110

|

Product Description of lab extruder

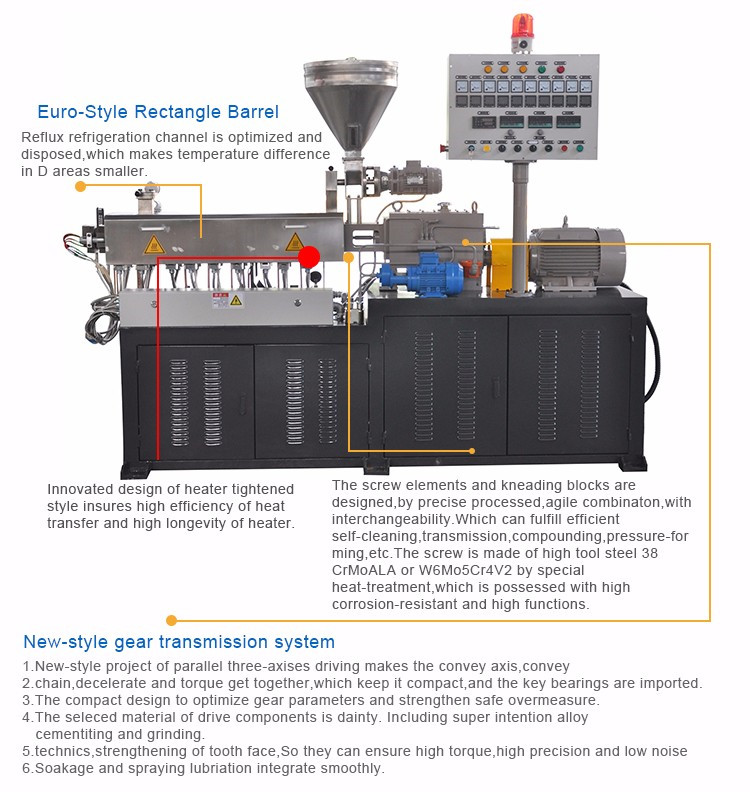

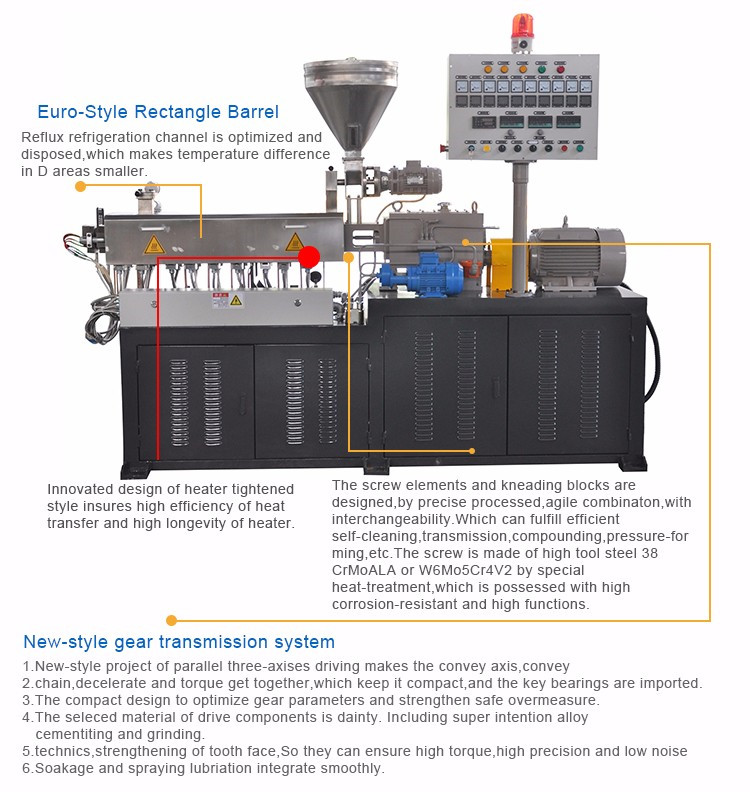

The machines are designed by suing the "toy bricks" principle, the screw configuration, barrel setup, L/D or mode of feeding and venting, screen changing, way of granulating, and the control mode can be optimally adjusted according to different materials properties and requirements in consideration of the versatility in each general applications.

lab extruder is widely used in general plastic, engineering plastic and thermal plastic rubber, etc polymer materials such as filling, reinforcing, toughening, etc blending modification, as well as the special fiber and special adhesive, etc processing fields.

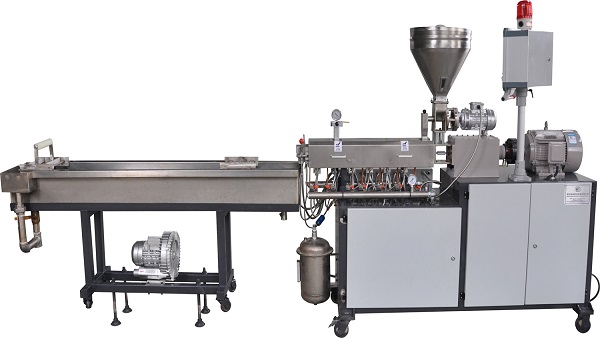

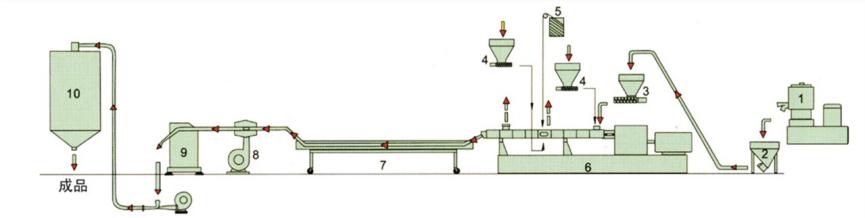

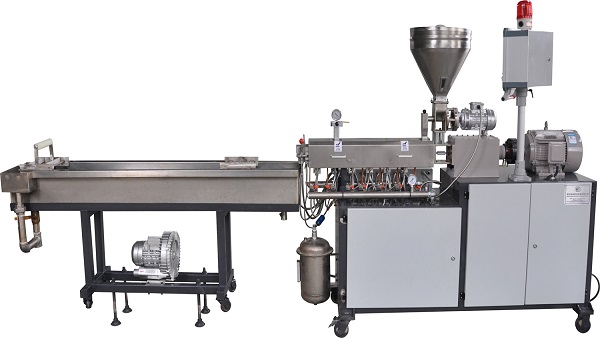

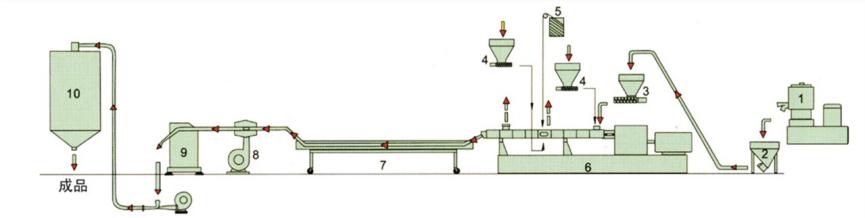

Equipments of laboratory extruder:

- Twin-screw metering feeder

- Mixer

- TSE series two screw extruder

- Water cooling strand pelletizing line

- PLC Electric control system

Applicaiton of lab extruder with water cooling strand pelletizing line:

Fibre reiforcement : glass fibre, carbon fibre reinforced PP, PA, PBT, ABS, PC, POM, PPS, PET, etc.

Incorporation of Fillers: Caco3, Talc, TiO2, carbon black,filled PE, PP, or EVA, etc.

Special Compounds: PPR pipe compounds, PE compounds for crosslinked pipes, tobacco filter compounds, etc.

High Concentration Color Masterbatches: PE, ABS, PS, EVA, PP,etc. with high concentration of pigments and other processing aids.

Masterbatches with Flame-retardants: PE, ABS, PS, EVA, PET, PP, etc. with flame retardants and other additives.