Flat Drip Irrigation Pipe Production Line Technical Specifications:

|

Model

|

Dripper Insertion Speed

|

Line Speed

|

Feeder +Buffer |

Perforation

|

Production/day

|

|

QDCO-DL200

|

800PCS/MIN

|

180-200M/MIN

|

1+0 |

2 Units

|

255000-280000m

|

|

QDCO-DL300

|

2000PCS/MIN

|

250-300M/MIN

|

1+1 |

3 Units

|

350000-430000m

|

|

QDCO-DL400

|

3000PCS/MIN

|

350-400M/MIN

|

2+1 |

4 or 6 Units

|

500000-570000m

|

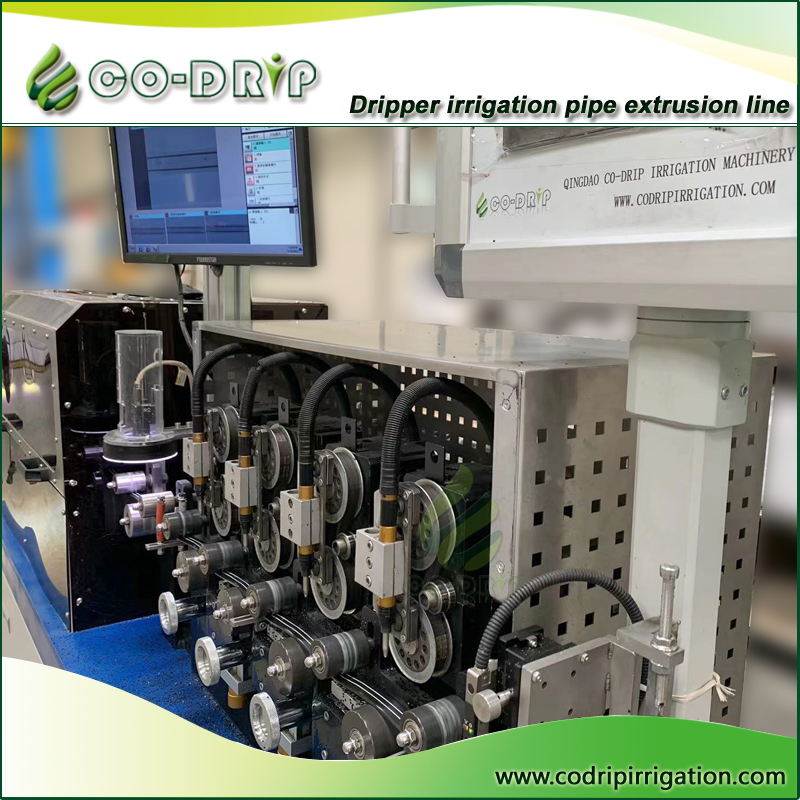

The whole Drip Irrigation Pipe Line Features:

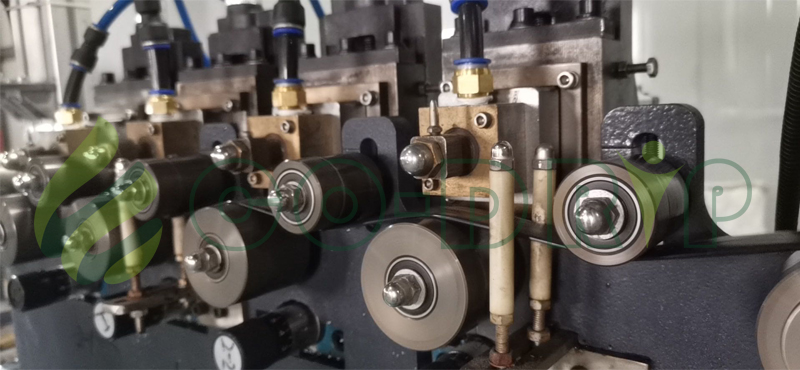

1、Different design for Perforation unit:

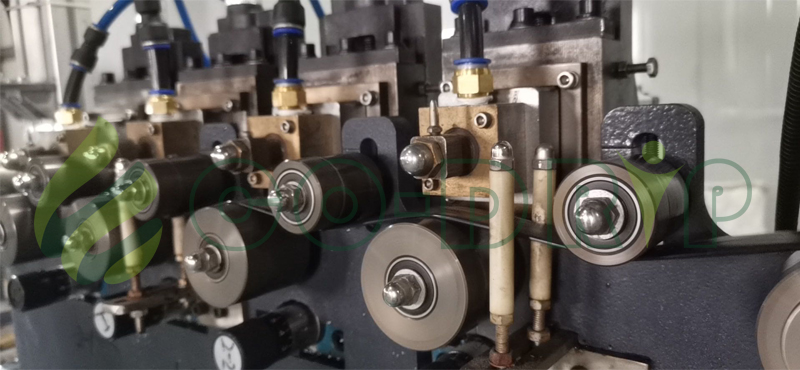

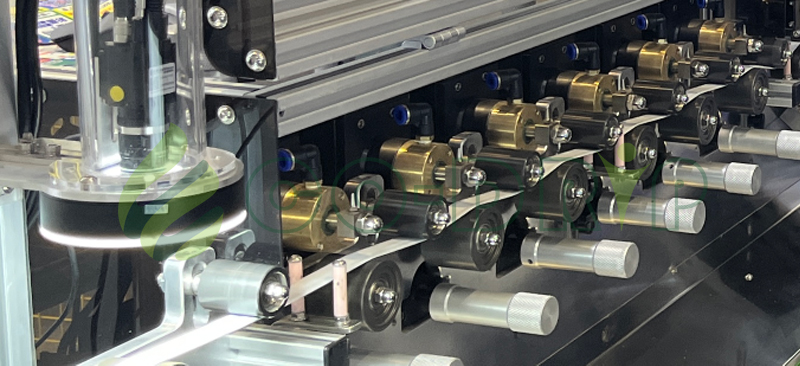

2 unit drilling unit,3 drilling units, 4 drilling unit, 6 drilling units, as per production line speed, and dripper type (single hole nano dripper or dual hole dripper) request. 6 pcs Perforation device is our CO-DRIP leading technology in this industry. Perforation unit with perforation capacity 800-5000 pcs drippers/Min.

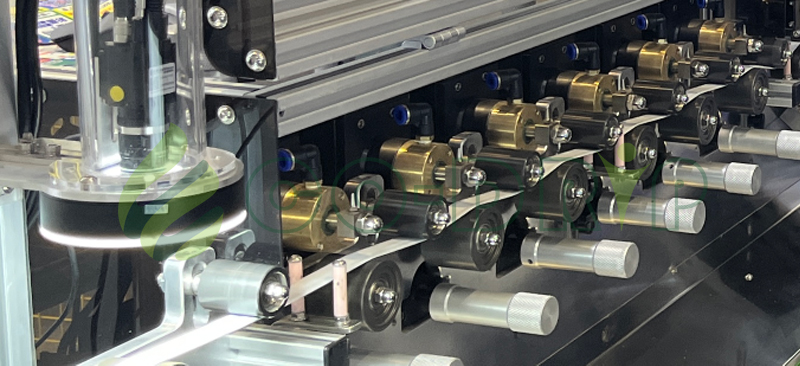

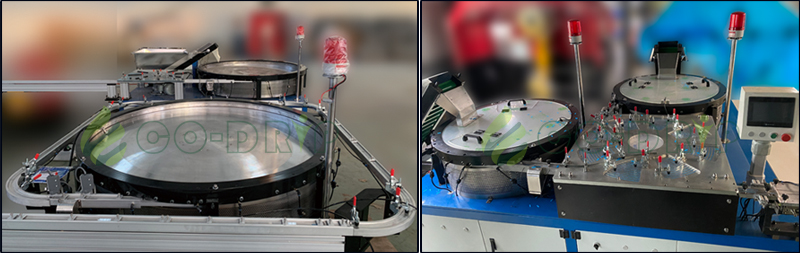

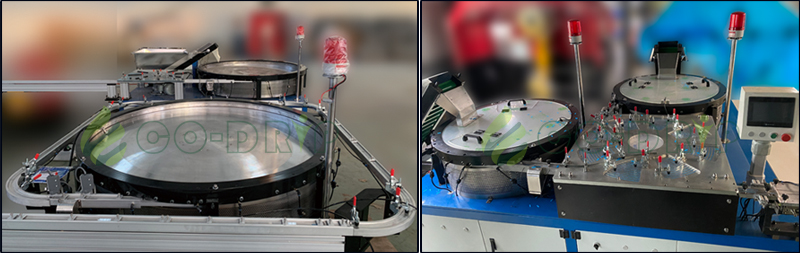

2、Dripper feeder & Sorting device, dripper buffer:

1 dripper feeder or 2 dripper feeder as option. Feeder Body diameter: 900mm,1200mm, 1400mm, 1500mm, 1600mm as option.

3、Extruder would feeding 100% recycling material. Pipe Thickness Range: 0.12 mm to 0.9 mm.

4、1 layer, 2 layers, or 3 layers irrigation pipe Co-extrusion technology.

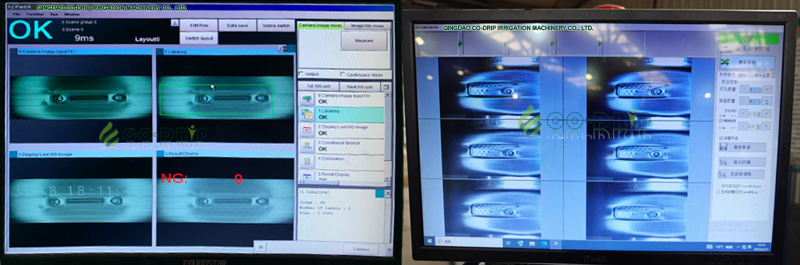

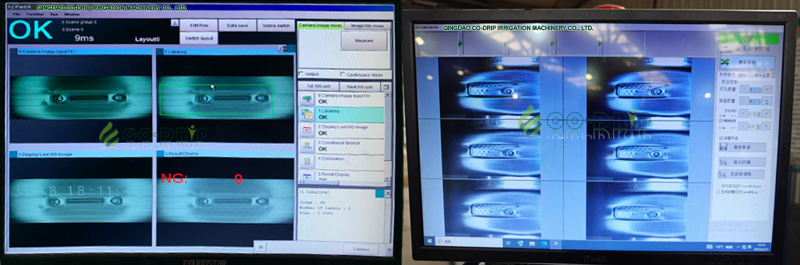

5、Online visual Inspection system for Perforation and Dripper spacing check with or without Auto correction facility.

6、Two station Auto Coiler with Synchronised Traversing, Auto pipe cut and auto bobbin change over.

7、PLC control whole line, and has Remote guidance and service support system.

8、Option: 4 Station Gravimetric Blender with Extrusion Process Control.

9、Option: Bimetallic Screw and Barrel ensure stable.

10、10 cm to 1000 cm spacing setting for different configuration pipe.

11、Uniform spacing/Group spacing/Plain Pipe/Sample features included in PLC.

Application of Irrigation Pipe :