Rotoplastic mold features:

(1) Low cost, the same size of the product, the cost of rotoplastic mold is about 1/3 to 1/4 of the cost of blow molding and injection mold.

(2) The product is formed once by rotoplastic process, acid and alkali resistance, corrosion resistance, wear resistance, fall resistance, easy to clean, good sealing, and can protect the product contents from damage.

(3) The corners of the products formed by the special process are 15%-20% thicker than the surface, and there is almost no material return in the production process, and the rotomizing process has a high material utilization rate.

(4) Good air tightness, high toughness, high resilience, to ensure no deformation.

(5) Rotoplastic products can be filled with foam materials to achieve thermal insulation and refrigeration.

(6) Simple maintenance, long service life, comprehensive use of cost-effective.

(7) Positioning foamed plastic buffer damping system, vibration, vibration conditions to ensure the safety and reliability of the carrier.

The construction protects the water meter from cold in winter conditions,

Protects the water meter and connections from freezing - the water meter visit hatch is bottomless, allowing passage

Heat from the bottom layer of the soil directly under the thermal insulation cover,

Easy reading and replacement of water meters - the water meter is located in the upper part of the meter visit hatch, which

Simplifies access,

Stability of the inspection hatch - the upper part of the water meter inspection hatch is further reinforced with strong reinforcements

Ribs, the high circumferential rigidity allows an independent installation, since a solid and stable base of the access hatch resists vertical loads, without the use of a concrete bed,

SIMPLE and fast INSTALLATION.

Rotational molding by YOUGE factory www.ygroto.com

Rotational molding is a high temperature,low volume,low pressure thermoplastic forming process.It mainly suite for producting hollow,one piece parts such as large oil or chemical tanks,kayaks ,canoes ,marine floats ,cases,coolers , furniture, carts, dispensers, pallets and so on . The PE material is UV resistant which can ensure the outdoor use of your products. YOUGE MOULD HIGH QUALITY ALLY CAST ROTOMOULD MANUFACTURING .

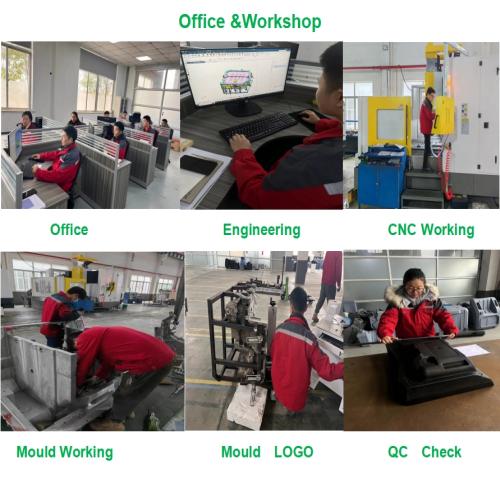

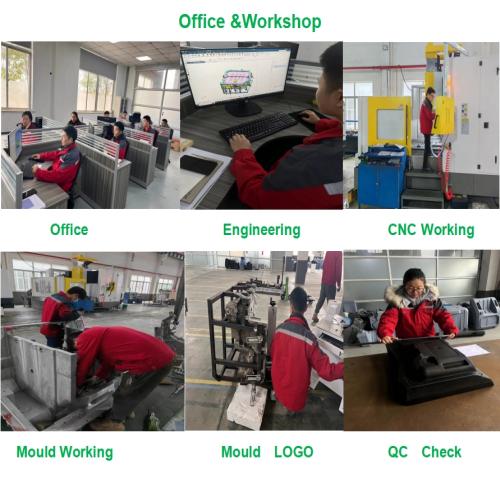

Why choose YOUGE factory 1.Superior Quality The professional R&D dept of our company having sufficient experiences in desingn and development. The skillful team were capable of avoiding any mistakes during the process of manufacture. 2.Competitive Price The cheap labor and land could save large expenses,the cost of production is accordingly low. We do our outmost to offer you the resonable price in order to facilitate the cooperation between us. 3.Best Services Our company is a leading export trade manufacture intigrating the products development,manufacturer and sales together.We are service-oriented and ensure that we can offer the best services to you.

packing:

rotational Mould : export wooden box

Plastic rotoplastic products : normally film and carton board protected

FAQ

1. About Uge Mould Factory

We are a professional rotary mold manufacturer in China, with more than 16 years of experience.

2. How do we guarantee quality?

Molds and products are inspected by UTG QC team.

100% pre-production samples before mass production;

100% final inspection before shipment;

3. What can you buy from us?

Rotary mold and PE products, tailored for you.

4. Why do you buy from us instead of other suppliers?

With more than 16 years of professional rotoplastic team, high-quality aluminum mold, fast delivery, reasonable price, from engineering design, mold to the final plastic product OEM service. Own QC team, transport arrangements.

5. What kind of services can we provide?

Acceptable delivery methods :FOB,CIF,EXW,DDP, express;

Accepted payment currency: USD, EUR, JPY, CAD, AUD, RMB;

Payment accepted: wire transfer, Letter of credit, Western Union;

Wire transfer deposits and balances

Languages: English, Chinese, Spanish