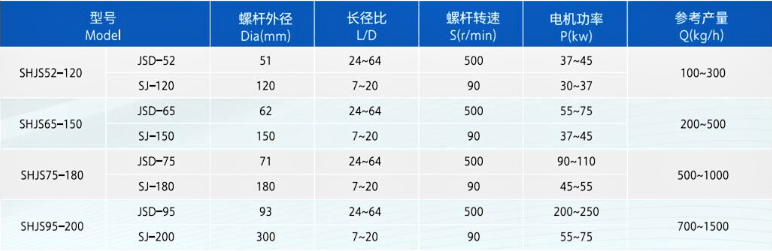

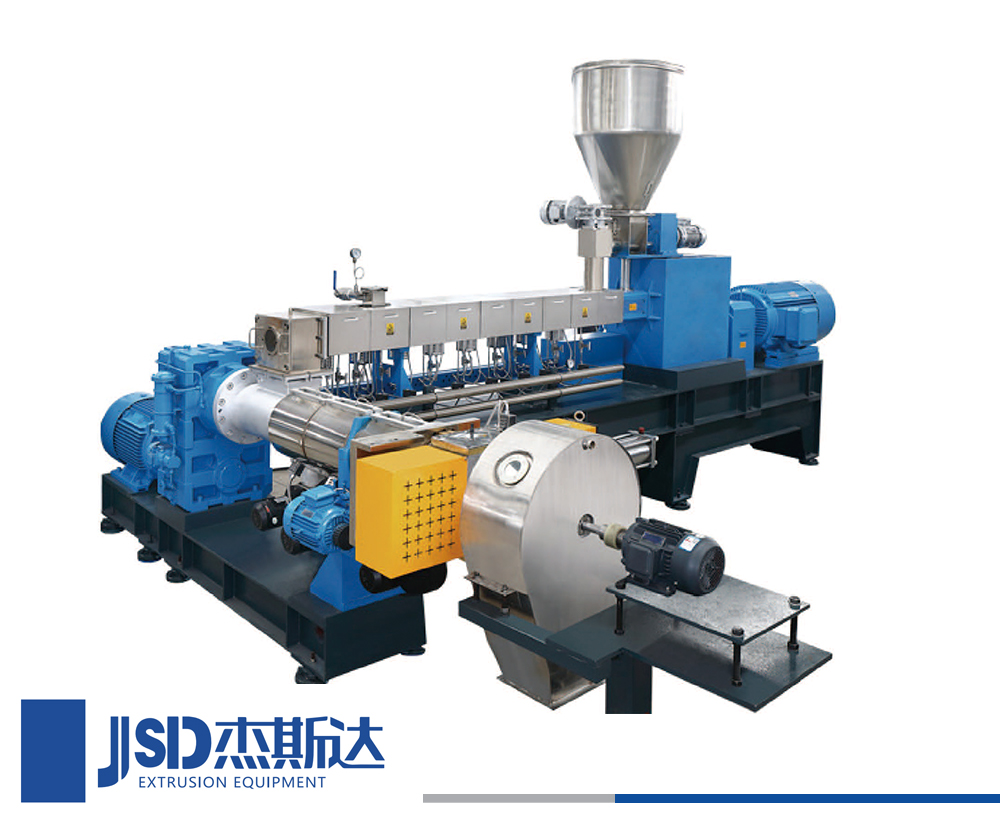

The upper-stage machine is the SHJ series parallel co-rotating twin-screw kneader. Utilizing the advantages of high speed, high shear and strong mixing of the twin screws, the materials can be fully plasticized and mixed. Thanks to the lack efhead back pressure, we can flexibly arrange the screw combinations for different materials to achieve the best mixing state of the materials.

The down-stage machine is the SJ series single-screw extruder. The low-speed deep groove feature of the screw provides a low-shear processing environment. At the same time, combined with barrel cooling, it prevents overheating and decomposition of plasticized materials during high-pressure extrusion: it is conducive to realizing different processes and maximizing the use of equipment. Advantages, greatly improve production efficiency;

Suitable for processing various heat-sensitive materials, such as PVC, XLPE, low-smoke halogen-free flame-retardant cables, shielding materials, etc.