1、 Definition and Characteristics

The co extrusion core layer foam board production line uses a co extrusion extruder to composite a hard PVC layer without foaming on the surface, greatly improving the surface hardness of the foam board. The production line is stable and technologically advanced, capable of producing co extruded core foam boards with excellent performance.

2、 Composition of production line

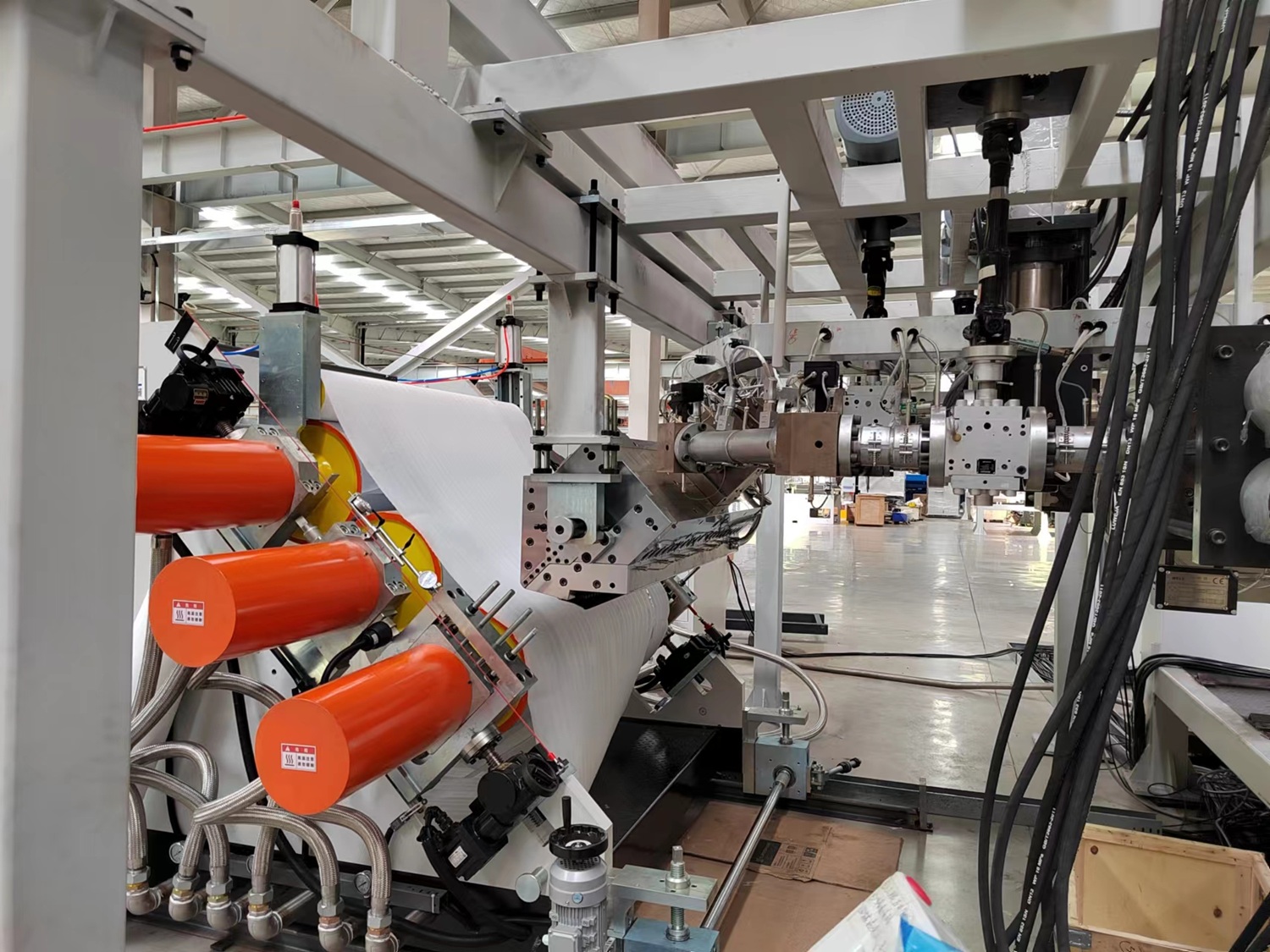

The co extruded core foam board production line usually consists of the following main equipment:

Conical twin-screw extruder: used for extruding core foam materials.

Sheet metal mold: Shapes the extruded material into the shape of a sheet metal.

Forming table: carry out shaping treatment on the board to ensure the stability of the size and shape of the board.

Traction and cutting auxiliary equipment: Pull the sheet forward and cut as needed.

3、 Technical parameters

The co extruded core foam board production lines of different manufacturers and models may have different technical parameters, but generally include the following aspects:

Production product width: usually adjustable within a certain range, such as 1220mm.

Production product thickness: adjustable within a certain range, such as 3-30mm.

Extruder model: such as SJSZ-80 × 173 (core layer extrusion)