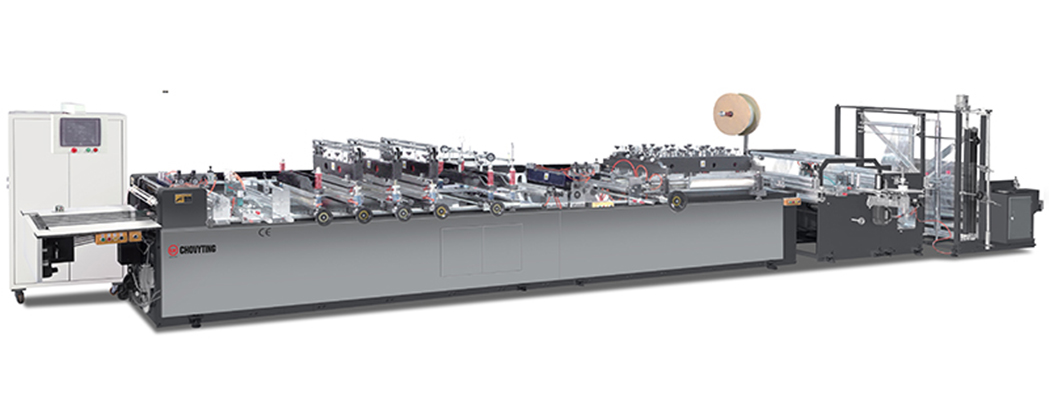

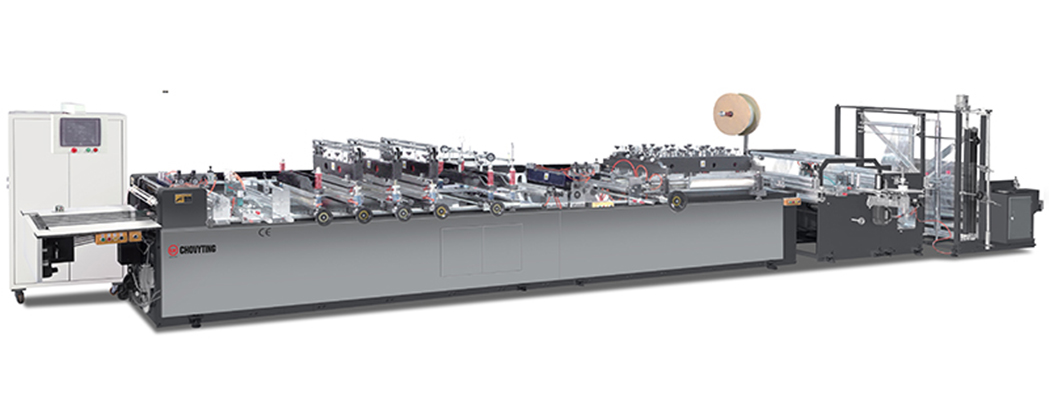

Heavy Duty Multifunction Laminated Bag Making Machine

3 side sealing pouch / zipper pouch / stand up zipper pouch

1.ONE SET BREATHING HOLE PUNCH WITH 6/8/10MM MOULD FOR REPLACING USE

2.ONE SET V NOTCH PUNCH

3.WASTE FILM COLLECTOR

Servo motor:Yaskawa Japan

Inverter: Yaskawa Japan

Photocell: Datalogic Itlay

PLC control: Panasonic Japan

Certification: CE/ISO:9001

Standard device

1.ONE SET BREATHING HOLE PUNCH WITH 6/8/10MM MOULD FOR REPLACING USE

2.ONE SET V NOTCH PUNCH

3.WASTE FILM COLLECTOR

Optional Device

Round double cutting system for cutting bagDouble unwindFilm storage system for non stop when film roll finish upDoypack stand sealing knife

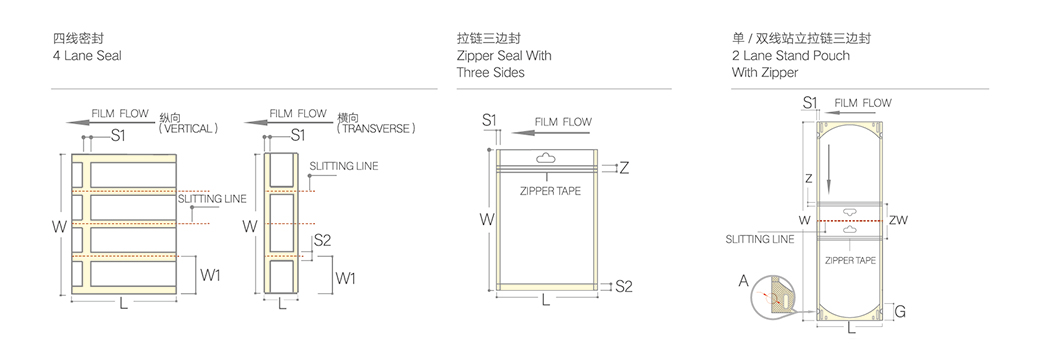

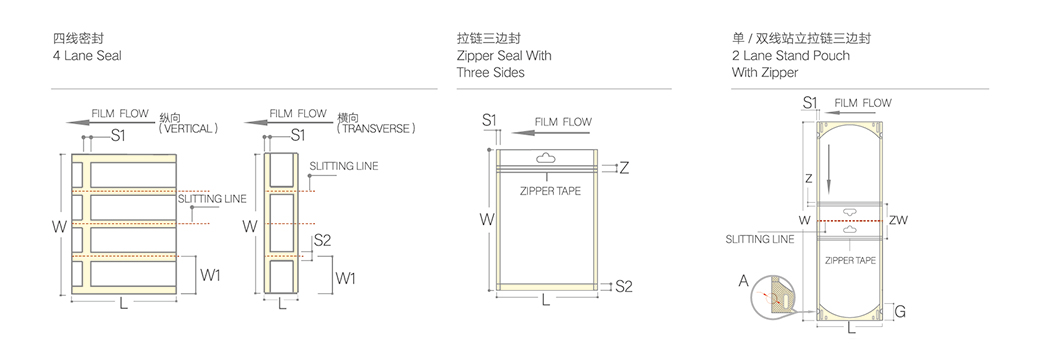

| L( Bag Making Length) |

50-420mmX 6N (N=SKIP) |

Unwinder Rolls Film Width |

1200mm |

| W(Bag Making Width) |

100-580mm |

Unwinder Diameter Of Roll |

800mm |

| W1(Single Lane Width |

75-580mm |

Speed Of Bag Making |

|

| S1( Bottom Seal Width) |

5-60mm |

3 Side Sealing Bag |

170pcs/min |

| S2( Vertical Seal Width) |

10-60mm |

Zipper Bag |

150pcs/min |

| Z( Zipper Width) |

13mm |

Stand Up And Zipper Bag |

150m/min |

| ZW( Double Line Zipper Bag Central Distance) |

60mm |

Line Speed |

40m/min |

| A(Punch Diameter) |

16mm |

Dimension Of Machine L*W*H |

14.5*

2.2*2m |

| G (Bottom Gusset Depth) |

25-60mm |

Air Compressor |

0.6mpa( 6kgf/cm2) |

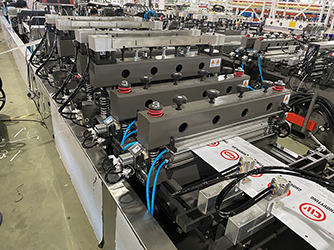

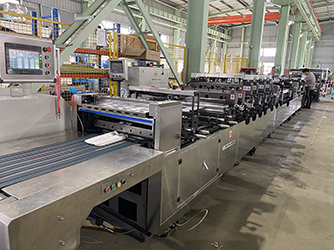

Details Images

|

|

|

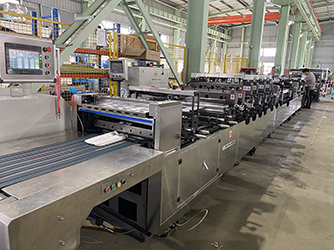

Single unwinding without transverse deviation correction (with pneumatic feeding)

|

Triangle folding + traction mechanism

|

Triangle folding + traction mechanism

|

|

|

|

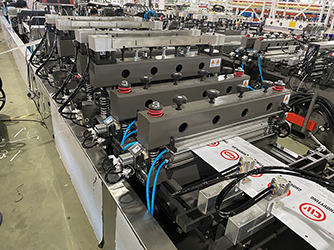

Vertical sealing 5 groups, used for sealing three side sealing, standing bag bottom sealing, etc.

|

Horizontal sealing part: (3 groups, cast iron type)

|

Collection desk part

|