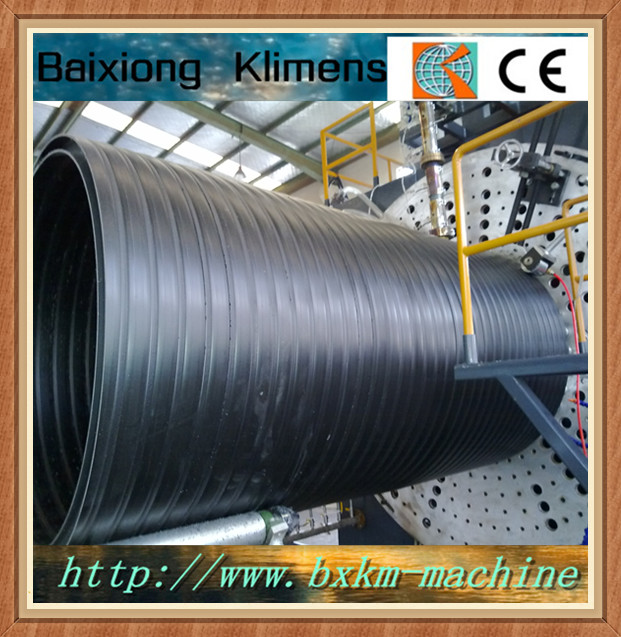

HDPE winding pipe production line

1. Product Specification(mm).

Φ200 to Φ3000

Each specification divides two grades, ring stiffness: S1 is 4KN/M2 , S2 is 8KN/M2

2. Extruder:

Main technical standards | SJ90 single screw extruder | SJ65 single screw extruder |

Screw diameter(mm) | Φ90 | Φ65 |

Ratio of length and diameter | 33:1 | 30:1 |

The screw speed(r/min) | 95 | 95 |

Main electrical engineering power(KW) | 90 | 45 |

Heating power(KW) | 40 | 22 |

Max. output (Kg/h) | 350 | 150 |

3. Application & Features:

(1) The pipes we produced base on high density polythene (PE) as main material.

(2) The rectangle pipes are extruded by the first extruder and then enter into the twine form machine , at the same time , the second extruder spray the rubber strips and then squeeze to reunite it.

(3)This kind of pipes have many extremely excellent characteristics, such as , corrosion resistant light , easy to fix , long life time (50years),etc.

lt is widely used for sewer in super high-way, municipal construction , flats , athetic field, square , mine agriculture , and bridges etc.

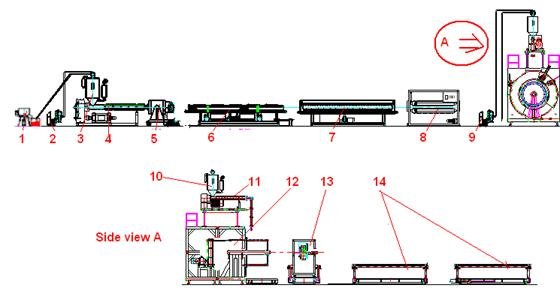

winding pipe production line

spiral pipe productiion line

Item | Machine | Quantity |

1 | Mixer | 1 set |

2 | Vacuum loader | 1 set |

3 | Hopper dryer | 1 set |

4 | Single-Screw Extruder With PLC control cabinet | 1 set |

5 | Die & Head & calibrators for profiles as required pressure class | complete set |

6 | Vacuum calibration tank | 1 set |

7 | Extended cooling tank | 1 set |

8 | Haul off unit | 1 set |

9 | Vacuum loader | 1 set |

10 | Hopper dryer | 1 set |

11 | Single screw extruder | 1 set |

12 | Winding forming machine | 1 set |

12.1 | Winding forming moulds | 1 set |

13 | Pipe Cutting Machine | 1 set |

14 | Pipe discharger | 1 set |

15 | PLC control cabinet for glue extruder and winding machine and cutting machine | 1 set |

HDPE winding pipe production line

Big diameter drainage pipe production line

Spiral pipe production line