Introduction of aluminum-plastic composite pipe production line:

Plastic composite pipe suitable for underground hot water supply pipe, has better thermal insulation, corrosion resistance. Because the inner wall is smooth, the resistance of the fluid is small, and because of the arbitrary bending, so the installation and construction is convenient. Qingdao HuaSu Machinery Manufacturing Co., Ltd. developed production of aluminum-plastic composite pipe equipment, unique design, stable performance can continue, the production of various specifications of aluminum plastic composite tube.

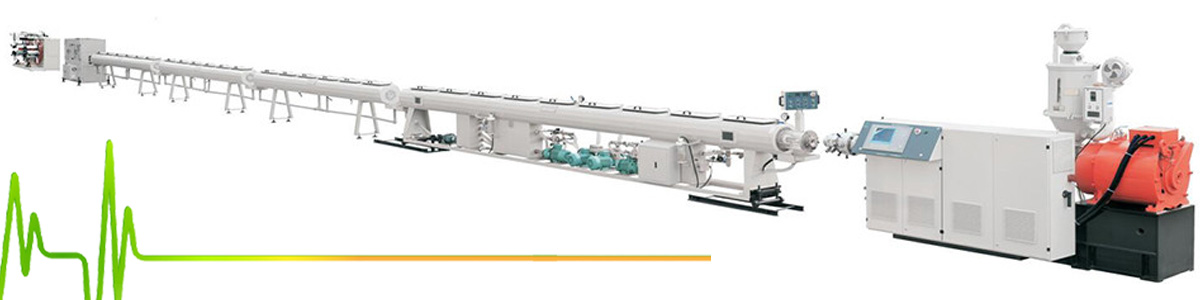

The production line including single screw extruder, coextrusion mould, vacuum calibrating tank diameter, spray water tank, traction machine, welding machine, welding machine, cutting machine, double station crimping machine, control system.

Single screw extruder: selection of Zhejiang Shuanglin Machinery Co., Ltd, single screw, heating ceramic, plastic raw material is heated evenly, good plasticizing effect, to ensure raw materials to be stable and efficient extrusion.

Coextrusion mould: unique five layer coextrusion die ensures the stable production of high quality aluminium plastic composite pipe, advanced fixed size technology to ensure the forming quality of aluminum-plastic composite pipe.

Vacuum tank diameter: box made of high quality stainless steel plate with ABS faucets with anti impurity blocking design, the use of long life, the frame can be adjusted in three-dimensional, cover with riding wheel mechanism.

Spray tank: the box is made of stainless steel, a transparent soft curtain PVC. Good cooling effect.

Traction machine: the frequency conversion speed adjustment, pneumatic pressing, and the whole production line synchronization.

Welding machine: according to the welding method, I divide the equipment into ultrasonic lap welding production line and butt argon arc welding line.

Ultrasonic lap welding process: a molding method of the, it is using the ultrasonic frequency, oscillation of welded joints of local heating and surface cleaning, then pressure is applied to achieve one of the welding pressure welding method.

Argon arc welding technology of docking: butt argon arc welding, weld tight finish, high strength, product appearance, quality reached the European standards; inlet connected to the belt welding machine, aluminum roll type forming welding and pulling, spear transformation welding, extrusion lamination, and the replacement of the mold is simple and time-saving, high rate of finished products.

Welding station: double station storage rack continuously and efficiently carry aluminum belt to the aluminum belt welding machine.

Dual station receiving machine: automatic correction device can guarantee winding accurate, save time.

Control system: PLC control system, man-machine interface.

Main products are: corrugated pipe extrusion machine, bellows mechanical equipment, corrugated pipe, corrugated pipe production line, corrugated pipe extrusion machine double wall corrugated pipe production line, double wall corrugated pipe extrusion machine, double wall corrugated pipe, double wall corrugated pipe extrusion machine, double wall corrugated pipe machine, extrusion machine, pipe production line, pipe machinery, plastic machinery, extrusion machine, extrusion machine, PE pipe production line, PE extrusion machine, PE pipe machine, PVC pipe equipment, PVC pipe production line, PVC extrusion machine, PVC pipe machine, spiral pipe production line, spiral pipe extrusion machine, spiral tube machine, plastic extruder, extrusion production line, corrugated pipe, double wall corrugated pipe, silicon core pipe production line, silicon core pipe extrusion machine, silicon core pipe machine, carbon carbon pipe production line, pipe extrusion machine, carbon tube machine, PVC profile production line, PVC extrusion machine. Corrugated pipe extrusion machine, bellows mechanical equipment, corrugated pipe, corrugated pipe production line, corrugated pipe extrusion machine double wall corrugated pipe production line, double wall corrugated pipe extrusion machine, double wall corrugated pipe, double wall corrugated pipe extrusion machine, double wall corrugated pipe machine, extrusion machine corrugated pipe extrusion machine, corrugated mechanical pipe, corrugated pipe, corrugated pipe production line, corrugated pipe extrusion machine double wall corrugated pipe production line, double wall corrugated pipe extrusion machine, double wall corrugated pipe, double wall corrugated pipe extrusion machine, double wall corrugated pipe machine, extrusion machine corrugated pipe extrusion machine, corrugated pipe machine, corrugated pipe equipment production line, corrugated pipe, corrugated pipe extrusion machine double wall corrugated pipe production line, double wall corrugated pipe extrusion machine, double wall corrugated pipe, double wall corrugated pipe extrusion machine, double wall corrugated pipe machine, extrusion machine of PE/PVC double wall corrugated pipe production line of PE/PVC double wall corrugated pipe mechanical PE/PVC double wall corrugated tube equipment .