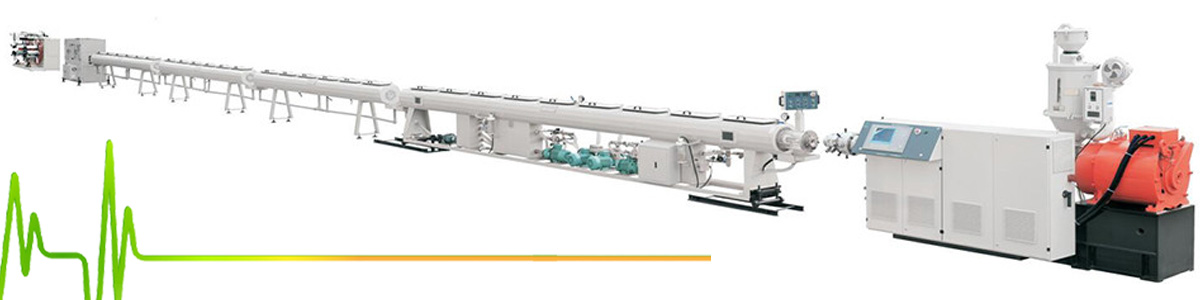

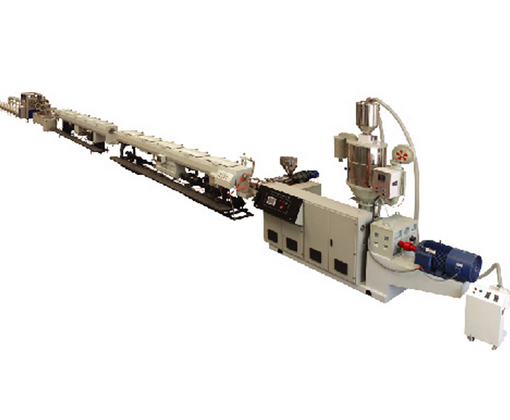

The production line is used to manufacture PP-R hot and cold water pipe with non-toxic, sanitary: heat, good insulation, pipeline welding process is simple and convenient, and can be recycled and other advantages.

Product features:

The production line by using the latest German technology manufacturing by high efficiency extruder, with high torque reducer, novel slotted barrel, LTM, screw, extrusion volume, low temperature of molten material, realize low temperature plasticization. The die is a screw - split - type head or a basket - head, and can be equipped with a static mixing system, and the internal pressure distribution is more uniform. The vacuum constant diameter box is two section type, the consummation water temperature, the water level and the flow control, the guarantee produces the high quality pipe. The production line has a little change, with different molds, screw and auxiliary equipment, can produce PE, ABS, PERT, REX-B tube and two kinds of plastic composite pipe with different materials. Also according to PPR, ppb unique processing performance design manufacturing of high efficiency extruder with imported reducer, novel slotted barrel, BM screw, squeezes out the quantity to be big, low temperature of molten material, energy-saving effect of significantly. The spiral split head can be equipped with the static mixing system, and the material layer is fully stacked with each other, and the inner wall pressure distribution is more uniform compared with the traditional bracket.. The special design of the vacuum constant diameter and cooling system, the stainless steel plate production, using multi - section water - mode cooling, to ensure that the high - speed production of thick wall tubes and large - diameter pipe requirements.

High degree of configuration, intelligent.

1) extruder: company according to PPR, ppb unique processing performance design manufacturing of high efficiency extruder with Hardened reducer, novel slotted barrel, BM screw, extrusion volume, low temperature of molten material, energy-saving effect significantly.

2) die: the spiral split head, the static mixing system, the material layer is more than this, compared with the traditional stent, the internal pressure distribution is more uniform..

3) sizing cooling: special design of vacuum sizing and cooling system, water tank is made of stainless steel, never rust by multi segment type water cooling mould ; ensure that the requirements of high-speed production pipe with thick wall and large diameter tube.

4) configure high-grade: extruder gear box, DC speed regulator, frequency control, programmable controller, touch screen, electronic control system, ink jet printer and so on are used imported famous brand products.

Production process:

Raw material + masterbatch & rarr; mixed & rarr; vacuum material & rarr; raw material drying & rarr; single screw extrusion machine & rarr; color line extrusion machine & rarr; spiral mould & rarr; diameter & rarr; vacuum spray shaping box & rarr; spray cooling water tank & rarr; inkjet printer & rarr; crawler traction machine & rarr; non chip cutting machine & rarr; pipe each other frame & rarr; finished product packaging testing .

Zhejiang Shuanglin Machinery Co., Ltd. Main multilayer composite pipe production line, PEX al PEX tubing production line, PERT pipe production line, PPR pipe production line, high speed pipe production line, plastic pipe extrusion line, HDPE pipe production line, PEX pipe production line, pipe extrusion production line, aluminum-plastic composite pipe production line.