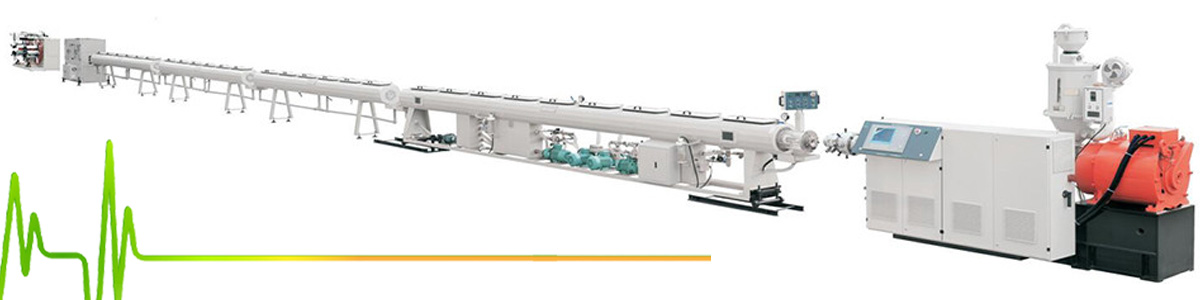

PE pipe production line selection of special HDPE, PP pipe, extrusion machine, screw with barrier and mixing head structure, the barrel with novel slotted barrel, plasticizing and mixing small fruit good, extrusion amount and very stable.

Production line characteristics 2 PE pipe production line is HDPE, PP large diameter thick wall pipe design of screw type die, the die with low melt temperature, good mixing performance, low mold cavity pressure, production stability characteristics. 3. PE pipe production line using proprietary technology of sizing and cooling system, the water film lubrication and water ring type cooling, in order to meet the requirements of HDPE and PP materials, to ensure high speed production of thick walled tube is the stability of diameter and roundness. 4. PE pipe production line using specially designed multi segment control vacuum degree of the vacuum sizing box, ensure the HDPE, PP pipe stable size and roundness. Extrusion machine, traction machine adopts imported brand-name governor and control, good stability, high precision and high reliability. 5. PE pipe production line operation and time by PLC for program control, is provided with a good man-machine interface, all process parameters can through the touch screen to set and display. Mark the assembly line dedicated extruder, production in line with the requirements of the national standard with color and markings of the pipe.

Production line process

Raw material + masterbatch & rarr; mixed & rarr; vacuum material & rarr; raw material drying & rarr; single screw extrusion machine & rarr; four-color line extrusion machine & rarr; basket type or spiral mold & rarr; diameter & rarr; vacuum spray shaping box & rarr; spray vacuum calibrating tank & rarr; spray cooling water tank & rarr; spray cooling water tank & rarr; printer ribbon & rarr; crawler traction machine & rarr; planetary cutting machine & rarr; pipe pile frame & rarr; product testing and packing.

Product introduction

PE water supply pipe is with special polyethylene as raw material by plastic extruder extruding forming, applied to urban water supply, irrigation engineering and agricultural irrigation engineering, especially in acid and alkali resistance, resistance to corrosive environment of the plastic pipe material. Due to the PE pipeline with hot melt, electric hot melting connection, the realization of the interface with the material of the integration, and can effectively resist the pressure to produce a ring to the axial force and impact stress and PE pipe does not add heavy metal salt stabilizer material, non-toxic, non scaling, not the breeding of bacteria, which can avoid the secondary pollution of drinking water.

Performance features

1 non toxic health: the material of the pipe material is non-toxic to the green building materials, not corrosion, no scaling.

2. Corrosion resistance: polyethylene is an inert material, except for a few strong oxidant, can withstand a variety of chemical medium erosion, no electrochemical corrosion, no coating.

3 convenient connection: the main use of polyethylene pipe hot melt connection and electric welding connection, so that the pipeline system integration. With good resistance to water hammer pressure ability, integration with the material of the pipe weld connection joints and polyethylene pipe of underground movement and the end of the load resistance capacity, greatly improving the the safety and reliability of water supply, improve water utilization rate.

4 flow resistance: the absolute roughness coefficient of the inner wall of the water pipe is no more than 0.01, which can effectively reduce the water consumption.

5. High toughness: polyethylene pipeline of water supply is a kind of high toughness pipe, the elongation at break is generally more than 500%, the base uneven settlement of the ability to adapt is very strong, a good aseismic performance of the pipeline.

6. Excellent winding: polyethylene tube around the polyethylene pipe to the disk file, to the supply of longer length, to avoid the large number of joints and fittings, increase the material for the economic value of the pipeline.

7 long service life: polyethylene pressure pipe safe service life of fifty years or more.

Application domain

1 urban water supply system.

2 food and chemical field transportation system.

3, ore slurry transportation system.

4 garden green network.

5 replacement of cement pipe, cast iron pipe and steel pipe.