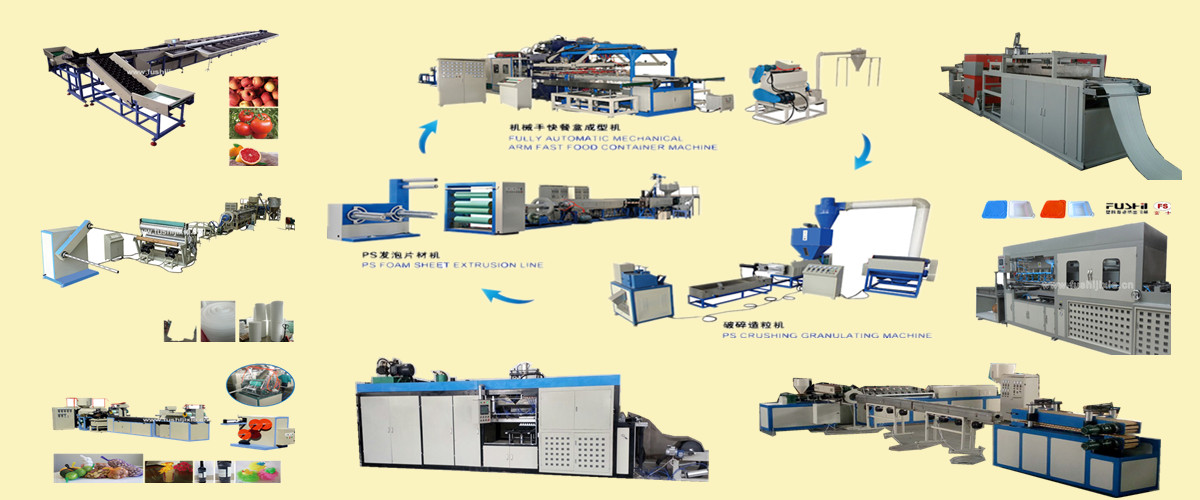

1. machine including three main parts:

1. PS foam sheet extruder: make PS foam sheet from raw material

2. Fully auto forming and cutting machine: make PS sheet to finished products, such as PS foam tray, PS foam box, Take away box,cosmetics packaging tray etc (we can design mould according to customer requirements)

3. Plastic recycle machine: recycle waste products to granules, the can mix with new material and put into PS foam sheet extruder again

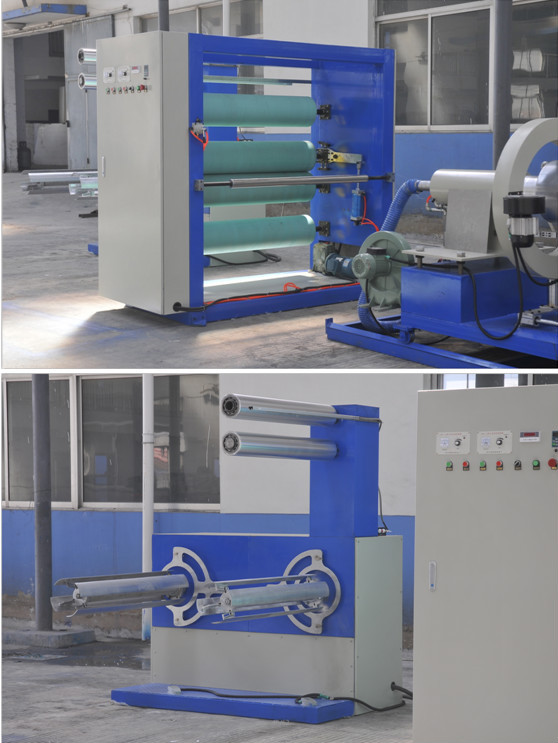

Picture of Fast Food Container Machine :

2. Each part introducing

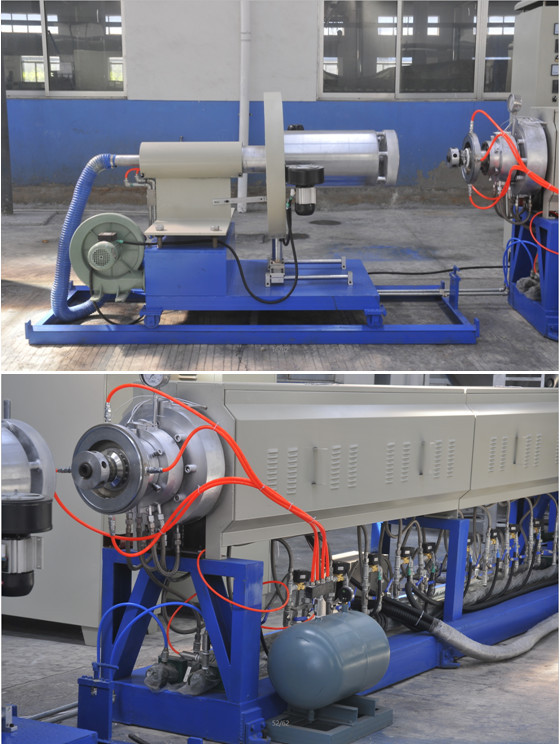

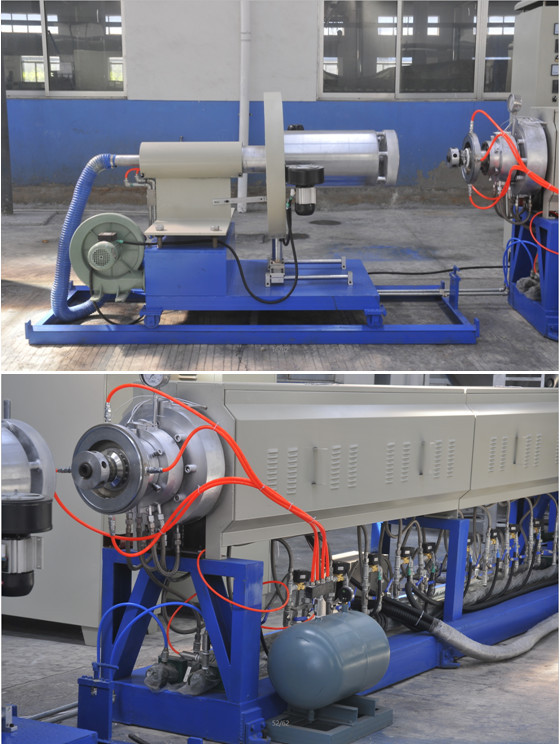

A. PS Foam Sheet Extruder

PS Foam Sheet Extruder uses a tandem screw technology to produce fine-block cell-structured

extruded ps foam sheet with high strength and a pearl and even surface, in a continuous roll, from polystyrene injection an eco-friendly blowing gas and additives. It has a user friendly operating system with inverter controlled driving, digital temperature control and so on.

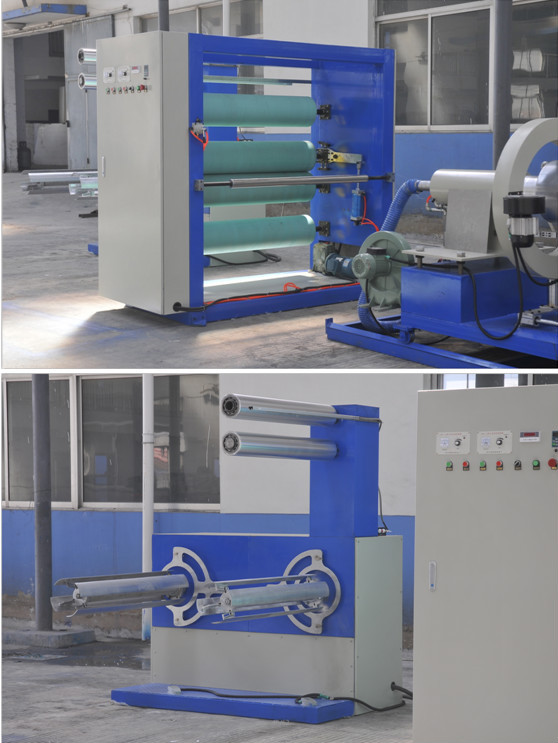

B. Fully auto forming and cutting machine

Fully automatic forming and cutting machine integrates forming, cutting and stacking (trimming) at the same time. It has the features of saving labor, improving efficient, lowing labor intensity and reducing production cost. It adopts PLC controller and touch screen to control the working program.Two workers are enough for whole production line.

The machine is plastic sheet forming equipment in one step with following process: transporting sheet—heating— forming—cutting—stacking —winding waste edge.

Main technical parameters of Fully automatic forming and cutting machine:

Model | Unit |

|

Max. forming area | mm | 1100×1400 |

Max. forming depth | mm | 80 |

Production efficiency | molds/min | 8-22 |

Cutting pressure | T | 60-120 |

Heating power | kw | 75-160 |

Total weight | T | 16-25 |

Installation size | m | 30×7×3 |

C. Plastic recycle machine

Plastic recycle and pelletizing machine is designed to reclaim the foamed polystyrene materials almost identically to new ones with its own superior filtering performance.

3.Product Pictures

This is just a part of product picture,different moulds can produce different products,We can make machine and mold according to customer requirements

We adopt export standard packing and we can help you to deal with the freight agent.

Pre-sale service:There are professional saleswomen will communication with you and assist you to complete the order.After signing the order, they will help you to monitor the progress.Any question,please let them know.

After-sales service:Engineers available to service machinery overseas;1 years of guarantee and lifetime maintenance.

If you are interested,please contact us.