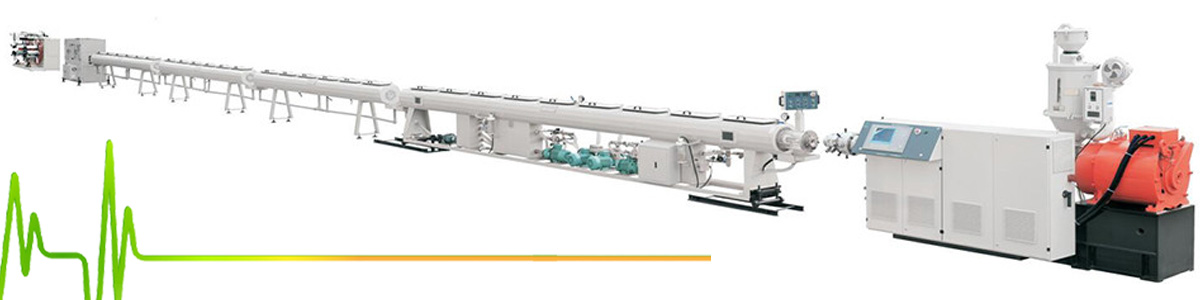

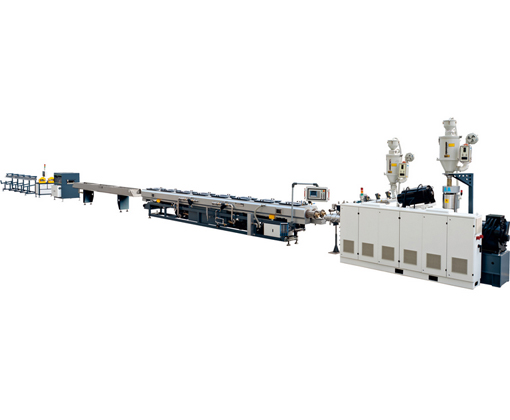

According to the experience of plastic machine development and design, a production line of two cold hot water PP PP-R pipe is developed..

Production line using energy efficient single screw extruder with special mould, production efficiency than single high-speed production line increased by 30%, energy consumption lower than 20%, also effectively reduced labor costs.

According to the production need to change the mouth die, core mold, and production of two different diameter or different pressure grade of pipe.

The production of PE-PT or PE tubes can be realized by the appropriate transformation of the production line..

The machine adopts PLC control and color large screen liquid crystal display screen composed of control system, the operation is simple, linkage across the board, machine adjustment, automatic fault alarm, the whole line appearance, stable and reliable production.