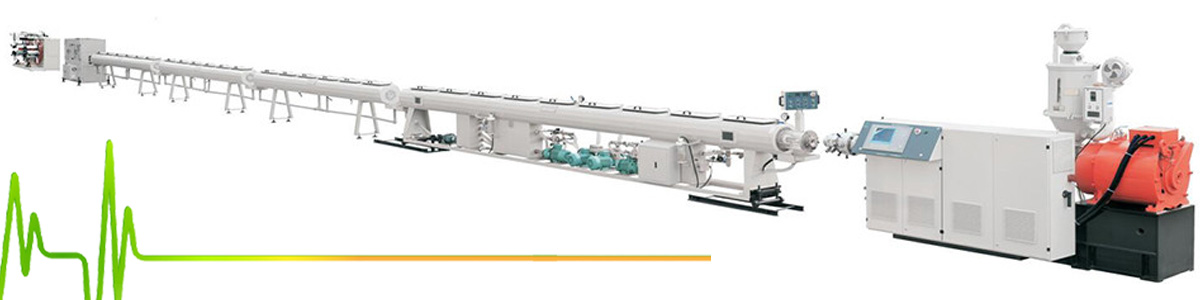

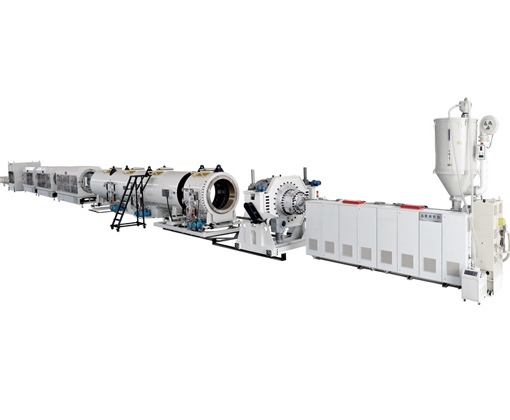

According to many years of plastic machinery development and design experience, in the introduction of foreign advanced technology and digestion and absorption, on the basis of self-developed HDPE water supply pipe and gas pipe production line. Has the unique structure, the design is novel, the equipment entire line layout is reasonable, the control performance is strong and so on. The products are widely used in the installation, and have become the first choice for the city gas transport pipe and the outdoor water supply pipe..

Production line with high efficiency single screw extruder and through the spiral or basket type mould by multi - Crawler traction machine vacuum sizing cooling and. As is known to all, large-diameter PE pipe are tractive pipe variety, Shuanglin specially developed rapid traction switching device, so as to solve the the problem. By the appropriate transformation part of the unit, you can achieve a two-layer or multi-layer co extruded, replacing the extruded layer material or add special materials according to the requirements of the use, such as flame retardant, antistatic, corrosion resistance, nano antibacterial materials, greatly improving the pipe use, reduce raw material consumption, thereby reducing the cost of pipes.

Production line using PLC control system, man-machine dialogue interface, simple operation, stand-alone adjustment, the full board linkage, automatic fault alarm, production and reliable.