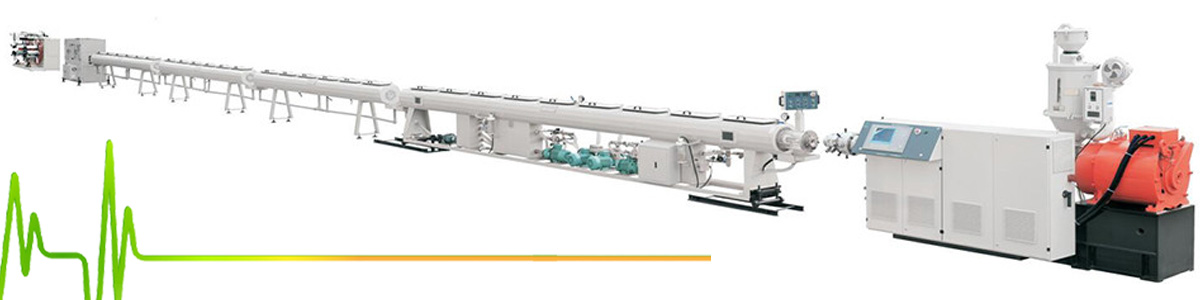

The machine adopts energy efficient conical twin-screw extruder and through special mould one-time extrusion four PVC pipe, effectively saving energy, improve production speed, saving covers an area of and manpower cost.

Designed for the PVC pipe design of non chip cutting machine, the independent variable frequency speed regulation, according to the cutting of the need to adjust the cutting speed, using the Hough clamping device, so the fixture and the service life is longer, product cutting surface is smooth, without burr, completely solve the plastic cutting dust pollution and chip dust problem. Incremental encoder length cutting, to ensure the length of the product, cutting precision.

For the four tube jet mobile device development inkjet printer, servo motor drive, so as to solve the problem of four tube jet printing speed.

Designed for the automatic control system of PVC pipe design, adopts Siemens PLC computer control, intelligent distributed the new scheme, the operation is simple, single adjustment, across the board linkage, fault alarm, beautiful appearance, high degree of automation, stable and reliable production.