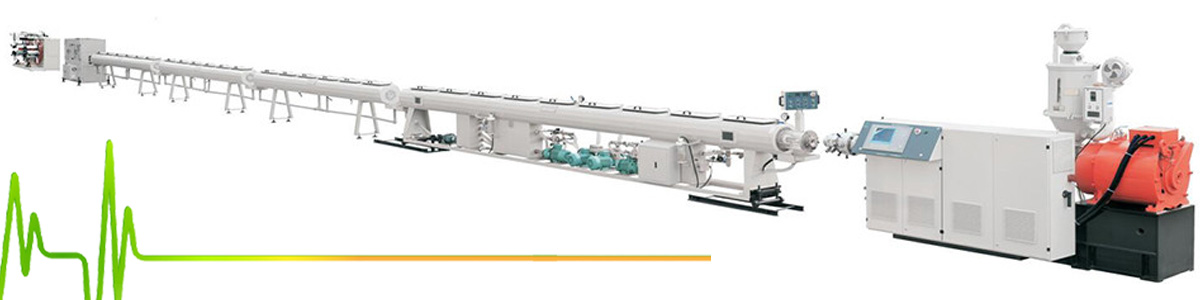

Single screw extruder

Single screw extruder for extrusion soft and hard PVC, PE and other thermoplastic plastics, processing a variety of plastic products, such as film blowing, pipe extrusion, pressing and pulling ribbon may also be used to melt granulation. Plastic extruder design advanced, high quality, good plastic, low energy consumption, the use of involute gear drive, with low noise, smooth operation, large bearing capacity, long life and so on.

Introduction

Single screw extruder in general effective length is divided into three sections, according to the screw diameter, screw pitch and screw depth determination three section of effective length, generally by each accounted for one third of the division.

High performance single screw extruder with the overall design of the double step type, strengthening plasticizing function, to ensure the high speed and high stable performance extrusion, special barrier comprehensive mixed refine design, to ensure the material mixing effect, high shear and low melting plasticizing temperature to ensure the extrusion materials of high performance at low temperature and low pressure measurement. Design concept and features: high speed, high yield extrusion on the basis of Gaoping.

Principle of single screw extruder & nbsp; & nbsp; & nbsp; feed opening last thread began called conveying material here requirements cannot plasticization, but to preheating and pressure compaction, past the old extrusion theory that material here is loose and later by proof material here is actually a solid plug, is where the material after being squeezed is a solid like stopper, like, so long as to complete the transportation task is its function. The second section called compression section when the volume of helical groove is changed from big to small and temperature to reach the plasticizing degree, here to produce compressed by the conveyor section 3, here compressed to a. This is called screw compression ratio - 3:1, some machine changes completed plasticizing material into the third paragraph. Is the third paragraph metering section here material keep plasticizing temperature, just like the metering pump as accurately, quantitative transmission melt material, to supply the nose. At the same time, the temperature is not below the melting temperature, in general slightly high.

Single screw extruder is mainly used for extrusion soft and hard PVC, PE etc. thermoplastic plastics used, and the corresponding auxiliary (including molding machine head), processing a variety of plastic products, such as film, pipe, plate, ribbons, also can be used. Plastic extruder design advanced, high quality, good plastic, low energy consumption, the use of involute gear drive, with low noise, smooth operation, large bearing capacity, long life and so on.

Single screw extruder purpose Pipe extrusion: suitable for PP-R pipe, PE gas pipe, PEX cross-linked pipe, aluminum-plastic composite pipe, ABS pipe, PVC pipe, HDPE silicon core pipe and all kinds of coextrusion composite pipe. Extrusion of sheet and sheet: suitable for extrusion of PVC, PET, PS, PP, PC, etc.. Other plastics such as wire, stick, etc.. Extrusion of profiles: adjusting the rotating speed of the extruder and changing the structure of the extrusion screw can be applied to the production of PVC, polyolefin, etc.. Modified granulation: suitable for various plastics blending, modification, enhanced granulation.

Idea The high speed on the high quality base, high-yield extrusion. The design concept of low temperature plasticization, ensure the high quality products of extrusion. The design of two order integral, strengthening plasticizing function, ensure the adjustment of high performance extrusion. The special mixing barrier, integrated design, to ensure the effect of mixing material. The high torque output, large thrust bearing. The gear, shaft for high strength alloy steel, carburizing, grinding processing. The high hardness, high smoothness, low noise. The PLC intelligent control, can realize the linkage between main auxiliary equipment. The easy to monitor the man-machine interface, easy to understand processing and machine status. The according to the need of replaceable control mode (temperature control). The material for the 38CrMoAL/A nitriding treatment, wear resistance. The strict temperature control precision, wind cooling and water cooling unite. The design of inlet is unique, has a perfect water-cooling device. The screw cylinder groove surface feed base set, with enhanced feeding function, high speed high yield extrusion provides guarantee.