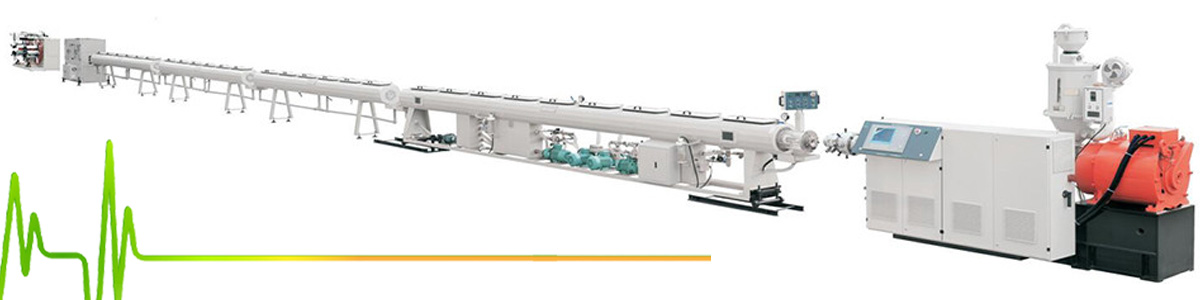

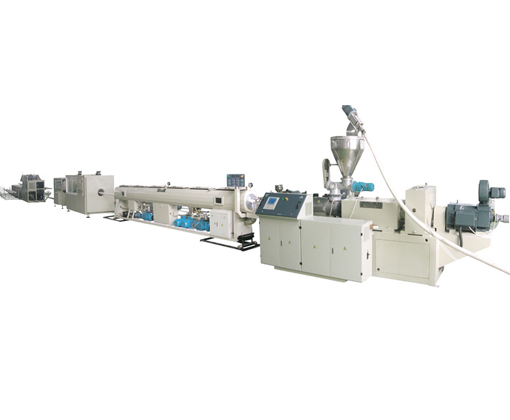

Twin screw extruder

Twin screw extrusion auxiliary unit mainly comprises a wire releasing device, straightener, preheating device, cooling device, traction device, meter, spark testing machine, wire device. Extrusion unit uses different equipped with auxiliary equipment are not the same, as well as cut off device, a drying device, a printing device etc.

Structure features

The notable feature of the split parallel twin screw extruder is that the cylinder can be divided simultaneously, and the inner liner of the screw and barrel can be assembled.Advantage 1, wear situation because it is easy to open, it can be found that the wear of the screw element, the bushing of the machine can be effectively repaired or replaced.. It's not necessary to waste the product when it is not found out.. 2, reduce production costs.

Manufacture of masterbatch, often need to change the color, if there is a need to replace the product, within a few minutes to open open type machining area. Besides, it can be through the observation of the screw on the melt profile to mixing process are analyzed. At present, the ordinary double screw extruder in the replacement of color, the need to use a lot of cleaning machine material, both time-consuming, electricity, and waste of raw materials. And split double screw extruder can solve this problem, color changes when, as long as a few minutes can quickly open the barrel, manual cleaning so that it can be no or less use of cleaning materials, saves the cost. 3, improve labor efficiency.

In the equipment maintenance, the ordinary twin screw extruder often first to heat, cooling system removed, and then the overall draw screw. While the split twin screw is not, as long as the release of a few bolts, the rotating worm gear box to lift the upper part of the machine can open the entire barrel, and then repair. This shortens the time of maintenance, and reduces the intensity of labor.. 4, Gao Niuju, high speed , the development trend of the twin screw extruder in the world is the development of high torque, high speed and low energy consumption. The effect of high speed is high productivity. The split - screw extruder belongs to this category and its speed can reach 500 rpm.. It has unique advantages in the processing of high viscosity, heat sensitive materials.

At high speed, the core technology of high torque, high torque gear box of asymmetric and symmetric currently only Germany and Japan manufacturers master the core technology, the speed can reach above 1800 rpm, and the master the core technology, only in Sichuan are installed, a science and technology, at present is the high-end materials processing manufacturers to choose one of the major, belonging to the domestic independent innovation projects encouraged by the state 5, wide application

Wide range of applications, can be applied to a variety of materials processing 6, high output, high quality.

The other advantages of ordinary twin screw extruder can achieve high output, high quality and high efficiency.

Application examples 1, glass fiber reinforced, resistant fuel granulation (such as: PA6, PA66, PET, PBT, PP. PC enhanced flame retardant, etc. 2, high filler material granulation (such as: PE, PP filling 75%CaCO.) 3, the granulation of heat sensitive materials (such as: PVC, XLPE cable) 4, Tony shaimuli (such as: 50% toner filling) 5, anti-static masterbatch, alloy, coloring, low filling blending 6, cable material granulation (such as: sheath material, insulation material) 7, XLPE pipe materials (such as: masterbatch for granulation of hot water crosslinking) 8, thermosetting plastics mixing extrusion such as: phenolic resin, epoxy, powder paint) 9, hot melt granulation, PU reactive extrusion (such as: EVA hot melt adhesive, polyurethane) 10, K resin, SBS stripping granulation