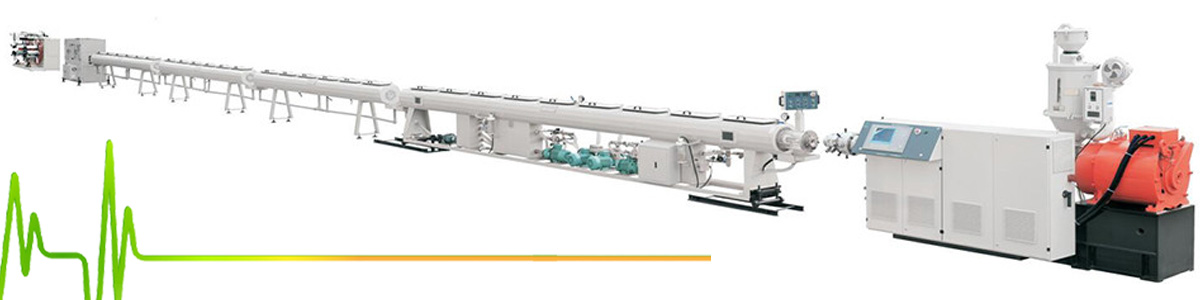

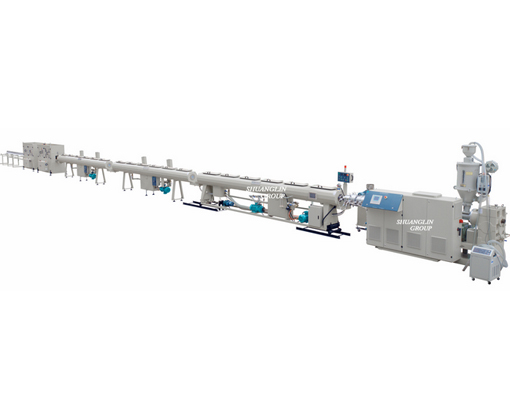

PPR pipe production line

PP-R drinking water system is widely used in developed countries in the world of new products, it in the hot and cold water transportation engineering with homogenous dissolves technology and its comprehensive technical performance and economic index is far superior to other similar products, especially its remarkable health performance, Huishou the whole process from production to recycling can achieve high requirements on hygiene and environmental protection & middot; products with of heat resistance, pressure resistance, thermal insulation, energy saving, long life and economic advantages, is widely used in today's developed countries, the new products.

PPR pipe production process

Raw material + masterbatch & rarr; mixed & rarr; vacuum material & rarr; raw material drying & rarr; single screw extrusion machine & rarr; color line extrusion machine & rarr; spiral mould & rarr; diameter & rarr; vacuum spray shaping box & rarr; spray cooling water tank & rarr; inkjet printer & rarr; crawler traction machine & rarr; finished product packaging testing PPR pipe production line.

PPR pipe production process encountered problems how to solve?

1, the surface of the pipe with focal trace may be due to high temperature of the fuselage or head; head and the filter is not cleaned; granular impurities; raw material for thermal stability is poor or heat stable dose is too small; temperature control instrument malfunction.

2, the surface of the pipe has black stripes may cause the nose temperature is too high, the filter did not clean.

3, the surface of the pipe is no gloss may be the mouth temperature is too low or too high.

4, the surface of the pipe material may be mouth mold temperature around the uneven; cooling water too hot; traction too slow.

5, the inner wall of the pipe may be rough mandrel temperature is low; the body temperature is too low; high temperature screw.

6, the inner wall of the pipe crack may be material impurities; the mandrel temperature is too low; the body temperature is low; the traction speed is too fast.

7, the inner wall of the pipe may have uneven screw temperature; the screw speed is too fast.

8, the inner wall of the tube bubble may be material moisture.

9. The thickness of the tube wall can not die, the core mold is not positive; the die temperature is uneven; traction instability; compressed air instability.

10, pipe bending may pipe wall thickness uneven; the nose around the temperature is not uniform; die cooling groove, traction cutting center is not right; cooling groove two ends of the hole is not concentric.

11, the product brittle may fuselage the degree of the body is not enough; screw speed too fast; the head temperature is too low; the viscosity is too high.

12. The radial difference between large diameter of tube and diameter of pipe is large (horizontal), and the traction speed is high (longitudinal).

13. The temperature of the feed is high, the water body is the water, the pressure is small.