film washing and pelletizing line

Stage One: film washing recycling

We are plastic machinery manufacturer, we have been in this field for over 15 years and our machines are CE and ISO 9001 certified. Our factory is close to Shanghai, which is convenient for your visiting and for us to deliver machines.

This line is the best proposal for PE and PP waste recycling, such as pp pe film; cling film, shop bags; rubbish bags; woven bags; jumb bags and so on, with full system configuration including crushing washing drying separating. Processing capacity :300kg/h, 500kg/h, 1000kg/h and more as per requirement by customer.

Input material : dirty PE/PP film and bags

Output material : clean and dry flakes ~ 40mm

In the washing line units after crusher , which parts touch PE/PP material, is made by stainless steel SS304

AC Motors on the machine : brand BEIDE ( Siemens Motor China Ltd. )

Inverters on the machine : brand ABB

Temperature controllers on the machine : brand Omron

Electric contactors and relays in the control panel : brand Siemens

System configuration:

| Item | Description |

| 1 | Belt conveyor with electric magnetic absorber |

| 2 | Crusher(with water) |

| 3 | Friction washing unit |

| 4 | Flotation(rising) washing unit |

| 5 | Centrifugal dewatering unit(or Squeezing dewatering unit) |

| 6 | Hot air flow drying unit |

| 7 | Silo |

| 8 | Electric control cabinet |

Main technical parameter

| Model | SWP-800 | SWP-1000 | SWP-1500 |

Caliber of the feeding gate(mm) | 800*700 | 1000*800 | 1500*1000 |

Compressing device for bottles (avoid bottles jumping inside the crushing chamber) | Motor:3.0kw |

| Diameter of rotating knifes(mm) | 450 | 535 | 800 |

| Number of rotative knifes(pcs) | 6 | 6 | 36 |

| Rotation speed of knifes(r/min) | 480 | 630 | 470 |

| Number of fixed knifes(pcs) | 4 | 4 | 6 |

| Diameter of sieve plate holes(mm) | 14mm for bottles 40mm for film | 14mm for bottles 40mm for film | 20mm for bottles 100mm for film |

| Capacity(kg/h) | 300kg/h for film 500kg/h for bottles | 500kg/h for film 1000kg/h for bottles | 1000kg/h for film 1500kg/h for bottles |

| Main motor power(Kw) | 37 | 55 | 110 |

| Figure dimension(mm) | 1850*1900*2700 | 2000*1900*2850 | 2550*2050*3930 |

Cooling water supplying required : 14 ~ 30 C degree, 100L/minute

All AC motors brand :BEIDE ( SIEMENS China )

Frequency inverter brand: ABB

Temperature controllers brand : Omron

Electric elements ( contactors, relays ) brand : Siemens

System configuration:

| Item | Descripyion | Qty |

| 1 | Belt conveyor | 1 set |

| 2 | Force Feeding unit(compactor) | 1 set |

| 3 | Single screw extruder with hydraulic screen changer | 1 set |

| 4 | Water ring die face cutting unit | 1 set |

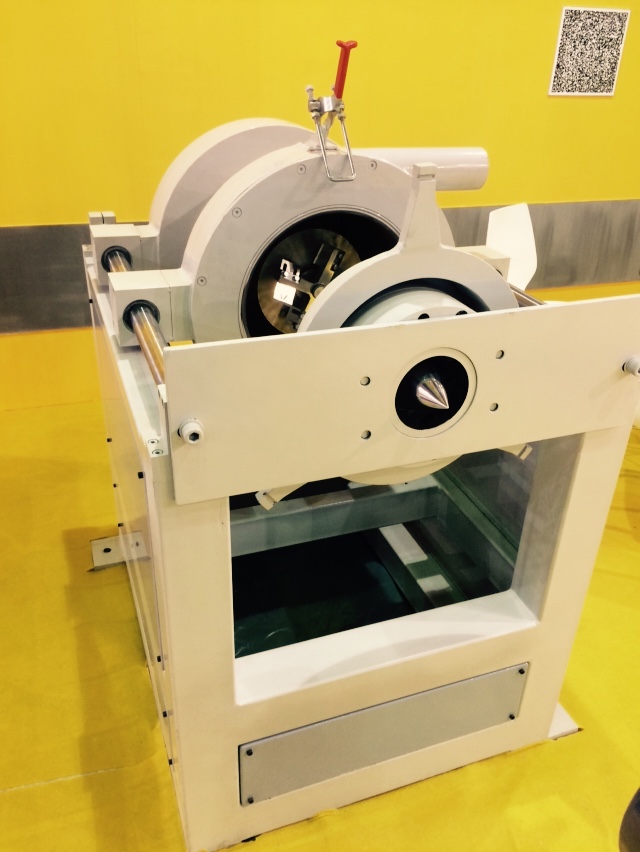

| 5 | Vibrosieve | 1 set |

| 6 | Centrifugal dryer | 1 set |

| 7 | Blowing conveyor and silo | 1 set |

| 8 | Electric contorl cabinet | 1 set |

--Water ring die face cutting unit