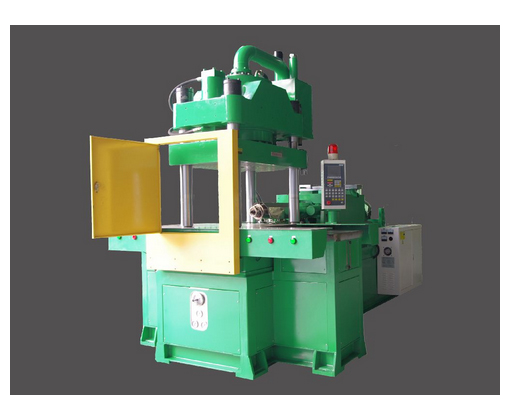

Mold with the bearing disc injection disc) (universal disk machine performance DRV3-3R-55T 55Tons vertical injection molding machine: upright clamping, erect to facilitate the embedding; multi station disk type (1 2 die), increase production capacity, high efficiency gear drive by plane self-lubricating wear-resistant film; cooling water by the central step water transport device (water supply can be synchronized 360 degree rotary or 180 degrees and transport water supply device, a complete cooling scheme); rotating fast accurate positioning the positioning cylinder positioning, positioning accuracy + 0.02mm, not positioning sub module, to protect the mold safety); the disc surface is plated with chrome anti rust, beautiful, durable, disk power can choose hydraulic motor and servo motor system.

Matching automatic insert and remove the system can realize unmanned operation of professional development of vertical injection molding machine automatic insert from a system, applicable to auto parts, glasses nose support, golf, drawstring products such as metal matrix and the inlaid into the object plastic molding operation, fully automated workflow process, high efficiency, low cost, collocation auxiliary device can realize unmanned industrial automatic production, reduce labor costs, stability and production efficiency and increase the yield.

1, nose care products: mold a fourteen, one minute 4~5 mode, the monthly output of 35~40 million pairs.

2, zipper products: automatic feeding, take the next molding, forming a wide range of length can be adjusted, each hour can be produced 450.

3, golf machine: full automatic molding, mold a out of eight, the monthly output of 45~50 million.

The main parts of the model are as follows:

(1) to surround the safety door and even to seal the board, the opening is installed four bit to the infrared protection (protecting the safety of the operator).

(2) touch screen control system for computer: Chinese / English touch type color screen (Fuji in Japan - Omron 10.4 "UG430) and PLC (Japan Omron), or choose Taiwan Nefful or Australian procheson host computer and 5.7 inches of liquid.

(3) electronic ruler: (Italy -GEFRAN), SSR PID precision temperature control (Japan - FUJI) external independent monitoring, screw speed display

(4) solenoid valve: (Japan -YUKEN), oil pump: (Japan -YUKEN), hydraulic motor: (European -DANFOSS), double proportional valve: (Japan -YUKEN). Disc powered by European -DANFOSS or choose servo motor drive: (Japan - MITSUBISHI)

(5): tight seal (-NOK), Palin: (-NSK) (Dongguan: motor, motor)