It is widely used in recycling plastic films like agriculture film, bags, PP woven bags and so on. With complete crushing and washing line, clients can make dry, clean film scraps from wasted material. The whole washing line could be "L" or "U" shape according to clients' workshop.

The working flow of this washing line is: belt conveyer → crusher → friction washer → float washer→dewatering/film squeezer/film densifier → dryer → silo. If the film is very dirty, some clients may add steam/hot washer for this washing line.

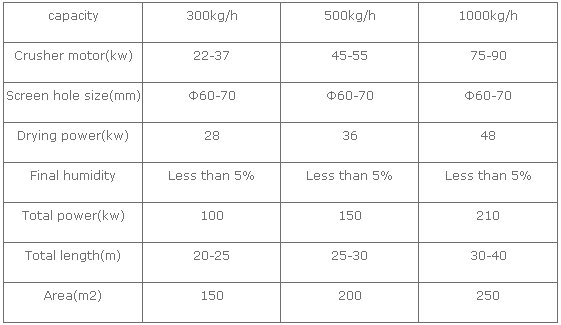

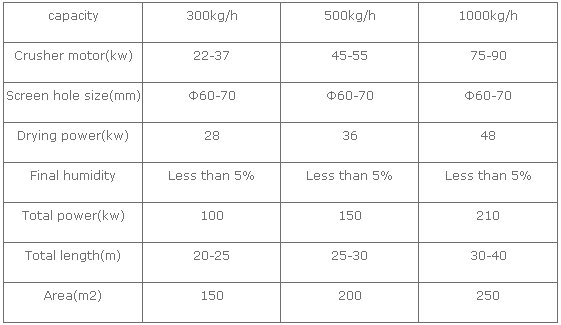

Main Machine Specification: