Specification

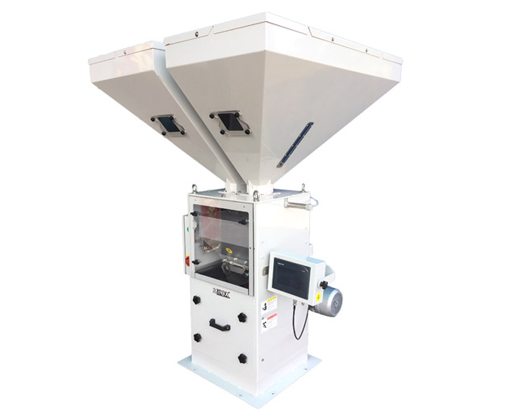

MGB series gravimetric blenders are designed for accurate dosing and blending of free-flowing virgin, regrind, additives or masterbatch, and is suitable for the use with injection molder or extruder where high accuracy (within1/100)is required. components are individually dosed using either motor driven screw feeders or pneumatic slide valves.

This series offers 2 to 4 components ,and max.throughput capacities up to 1000 kg/hr

Features

You can set the ratio or percentage of raw materials, and it is easy to operate it Precies and stable continuous operation It will conduct weighing and measuring for the next batch of raw materials ,When mixing raw materials Automatic compensation to the adjustment In the course of material ingredient adjusting ,the controller can automatically corect and preset the default value It can be installed on or by the machine It Can simultaneously control more than one weighing -measurement machines(standard) It is able to cope with suction machines to automatically fill materials Under weighing/volume Production mode ,the material mixing capacity is increased Weighing hopper and storage hopper are easy to be cleaned Weighing accuracy is 1/100 grams

|  |

Technical Parameter

Model | Ingredients | Micro Metering Valve | Max output kg/hr | Max. Batch

(kg) | Compressed Air Presure (kgf/cm2) | Mixing Motor Power

kw | Material Storage Tank | Weighing Pan Volume

(L) | Mixing Tank | Max. batch Quantity |

MMS-G1 | 4 | 4 | 4 | 60 | 1 | 6 | 0.09 | 12 | 2 | 8 | 60 |

3 | 3 | 3 | 70 | 70 |

2 | 2 | 2 | 150 | 150 |

MMS-G2 | 6 | 6 | 4+2 | 120 | 2 | 6 | 0.09 | 40 | 8 | 18 | 60 |

5 | 5 | 4+1 | 140 | 70 |

4 | 4 | 4 | 180 | 90 |

3 | 3 | 3 | 200 | 100 |

2 | 2 | 2 | 400 | 200 |

MMS-G5 | 6 | 6 | 4+2 | 300 | 5 | 6 | 0.2 | 48 | 12 | 25 | 60 |

5 | 5 | 4+1 | 350 | 70 |

4 | 4 | 4 | 450 | 90 |

3 | 3 | 3 | 500 | 100 |

2 | 2 | 2 | 1000 | 200 |

MMS-G10 | 6 | 6 | * | 600 | 10 | 6 | 0.37 | 100 | 32 | 60 | 60 |

5 | 5 | * | 700 | 70 |

4 | 4 | * | 900 | 90 |

3 | 3 | * | 1000 | 100 |

2 | 2 | * | 2000 | 200 |

MMS-G25 | 6 | 6 | * | 1500 | 25 | 6 | 0.75 | 150 | 65 | 120 | 60 |

5 | 5 | * | 1750 | 70 |

4 | 4 | * | 2250 | 90 |

3 | 3 | * | 2500 | 100 |

2 | 2 | * | 4500 | 180 |