Mechanical system:

1. Using the finite element analysis, a design precision casting forming, high rigidity, long service life.

2. The deep hole processing, the hot plate drill by thickening and nitriding process, the use of high precision,, even the temperature distribution.

3. Numerical control equipment, to ensure accurancy, precision design with key parts for processing.

4. High-end adjustment plane technology, highest can make fluctuation hot plate parallel degree of 0.02mm

Oil line system:

1. The oil line is integrated design concept, reduce oil route, modular inpact and noise.

2. The safe and energy-saving design, improve efficiency, reduce energy consumption.

3. Special design of high speed loop, and makes speed fast acting as smooth transition, and can make any speed adjustment

4. Indenpendent exhaust circuit design, make the exhaust of 100%.

5. Using high quality hydraulic components, stable and reliable.

discription:

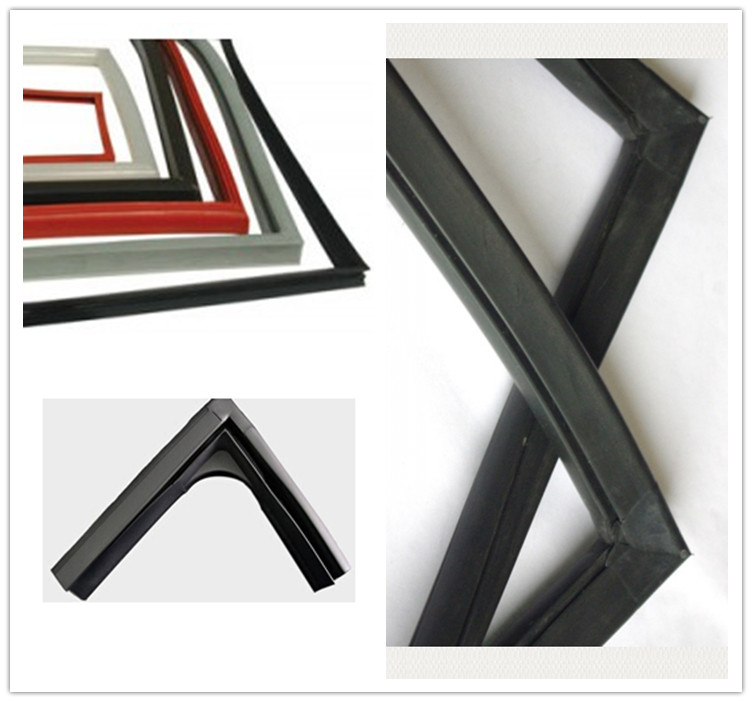

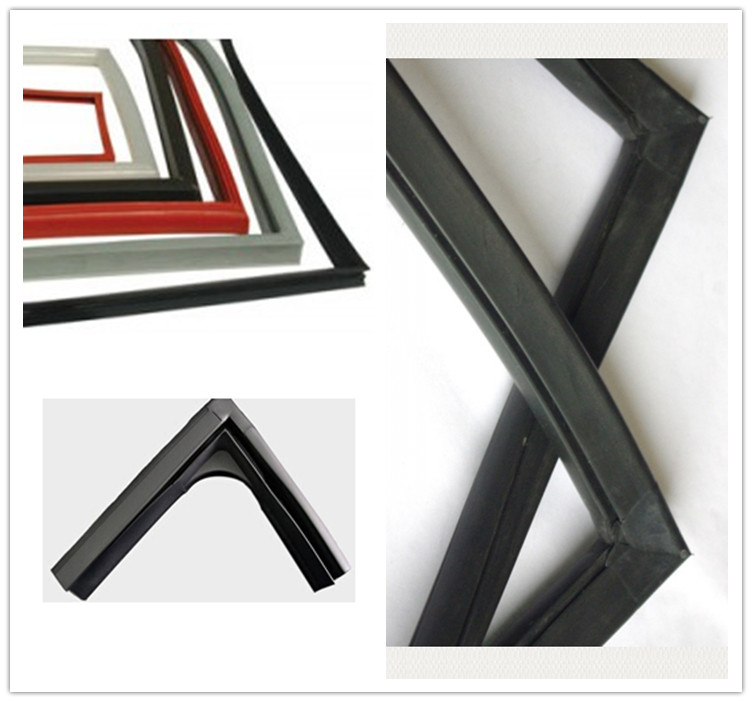

XZB-C-350 rubber hydraulic press molding machine is a kind of advanced rubber molding equipment. Main using for the rubber pieces with complicated shape and small volume. Specially suit for connect angles of all kinds of rubber sealing strip.

Feature:

This machine adopt C-type structure. Have the bigger operation space.

First, the lock mold oil urn lock the mold, then, the inject press oil urn press the material into the mould. It can make the products with high density, less scurf, stable mechanical properties and precise physical dimension, can protect the mold.

Each oil urn sealing strip adopt in NOK sealing strip from Japan, so dependable and have long service life.

adopt double vane pump, can provite large oil by low pressure, provide few oil by high pressure, make the machine operate fast and stable. can save the energy.

Have handle, half-automatic operate, easy operation, fast moving and low strength.

PLC control, control program stable, high accurancy.

adopt text-type interface, make each parameter establish convenience and fast.

The head of injection pressure with light-electric safety device, inprove the safety.

Equipped the hand-mold device.

Main technical data:

| mold-locking force | 35ton |

| the rated pressure of hydraulic press system | 23mpa |

| mold-lock stroke | 350mm |

| thermo-plate size | 300*350mm |

| the opening size of operation table | 45~390mm |

| the thickness of the mold | 50~300mm |

| mold-locking speed | >=30mm/s |

| injection pressure | 80mpa |

| injection stroke | 270mm |

| the specification of barrel | 40*150mm |

| heat power | 3kw |

| motor power | 3kw |

dimension 830*1385*2415mm

weight 2.1ton