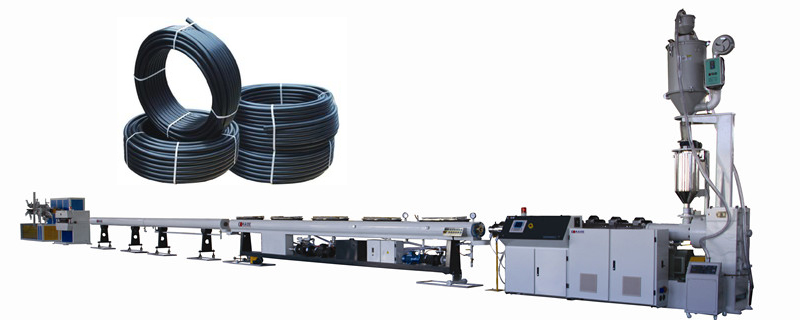

High Speed HDPE Pipe Making Machine/HDPE Pipe Production Line

KAIDE factory has focused on plastic pipe extrusion technology for more than 20 years, especially for high speed pipe line and multi-layer pipe line.

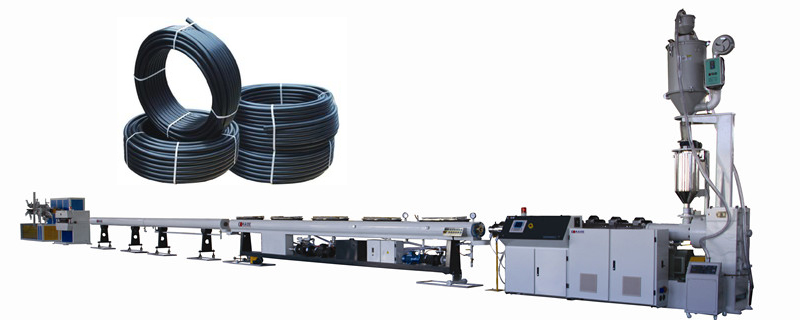

This HDPE pipe line are special designed for small diameter HDPE pipes, from 20mm to 63mm, in order to get a high speed of production to increase the production efficiency, reduce production cost, such as labor, electric and water consumption etc. The prodution line speed can reach to 40m/min to 50m/min.

Features of Pipe Machine:

◆ High efficient five section type screw and barrel, to ensure fast plasticizing & dispersion effect.

◆ Gravimetric material feeding system is to control material feeding according to pipe parameter & line production speed, to get high qualified pipe with constant weight per meter. It’s also have other benefits, such as shortening start-up time, saving raw material, simplifying operation.

◆ Spiral pressure-storage die head effectively overcomes the instantaneous fluctuation of extrusion pressure, realizing high speed pipe extrusion with stable pressure.

◆ Vacuum and calibrating system is further optimized based on our previous high speed pipe extrusion line technology; with better structure the pipe calibrating and cooling has become more effective.

◆ Fully automatic pipe winder; The whole process from reel changing to pipe cutting and winding is automatic. SIMENS PLC controlled separately and can be synced with line production speed.

◆ SIMENS programmable PLC control with big color touch screen. Having multi-point close-loop control and synchronous system, which ensure the easy and reliable operation of the line.

Technical Data:

Line Model | Screw Diameter | L/D | Production Speed | Nominal Power |

PE-75 | Ф75mm | 36:1 | 50m/min | 155KW |

PE-60 | Ф60mm | 36:1 | 35m/min | 104KW |

PE-80 | Ф80mm | 33:1 | 25m/min | 112KW |

PE-65 | Ф65mm | 33:1 | 15m/min | 76KW |