Home > Product

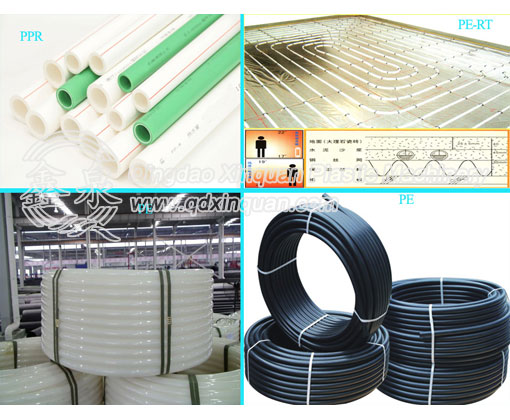

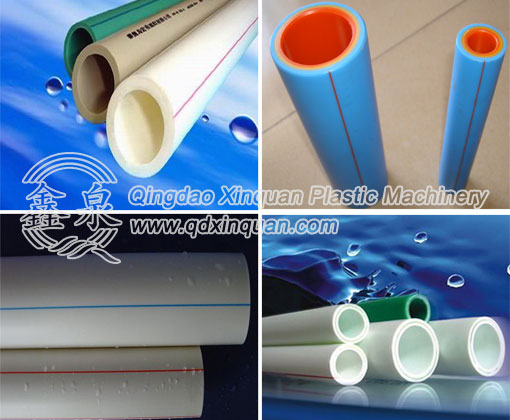

Categories > PPR, PE, PP Single Layer or Multi-layer Pipe Co-extrusion Production Line

PPR, PE, PP Single Layer or Multi-layer Pipe Co-extrusion Production Line 1426 Favorites

| Product Categories: PP/PE/PPR/PC/ABS/PVDF/PMMA Pipe Machine | |

| Packaging Details: | Trademark: |

| Certification: | |

| Payment Terms: | |

| FOB: | HS Code: |

| Loading Port:Qingdao | |

| Qingdao Xinquan Plastic Machinery Co., Ltd | |

|---|---|

| Company type: Manufacturer | Credit:

|

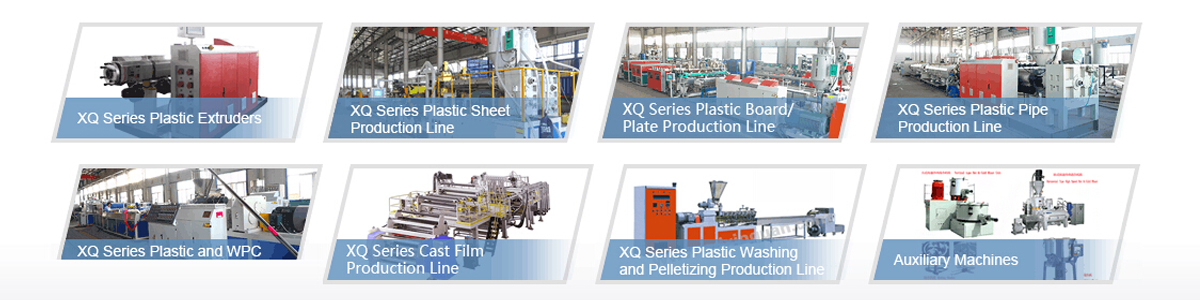

| Main products:Plastic Machinery | |

Contact Supplier

Reminding

Message has been sent successfully.