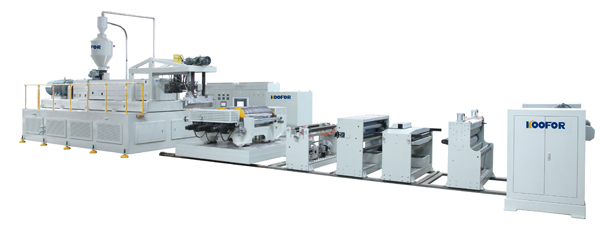

Technical index:

Model | Extruder | Installed Capacity | Output/ hr | Product Specification (mm) | Dimension (m) | Adopt Material |

PY1600 | TP95 Twin-screw | 350KW | 800KG/H | ≤1400/0.15-1.8 | 20×6×5.5 | RPET |

PY1000 | TP75 Twin-screw | 200KW | 400KG/H | ≤900/0.15-1.8 | 17×5×5 | RPET |

Features

◎ Appropriate for producing with PET,PP,PS,ABS,PLA,etc.

◎ Aodopt 100% recycled materials,which is easy to buy,lower priced and environment-friendly.

◎ The twin-screw extruder with same-direction,homo-parallel,multi-vent and no drying system,is well-plasticized, the IV decreases by 0.04.

◎ Totali installiation power consumption is only about 60% of the power consumption by single-screw.

◎ Output up to 400kg/hr or 800kg/hr of two models,non-discolouring and good ductility of sheet.

◎ The hole production line use human-computer interface to display,with PLC programming control system and temperature module which is easy to operate.

◎ This machine is equipped with side precision feeding device,producing with different color films.

◎ The screen-changer use candle-style long-lasting filter,which extends the period of changing each filter every 50 to200 hous(Option).