Product Description

QJ80B-120B Series extrusion blow molding machine is applied to blow hollow containers of various shapes and lengths including chemical barrels, toolbox, packaging, office equipment, automobile ventilating pipe etc. The machine can move upwards and downwards with the die storing up to 3kg-5kg raw materials. Equipped with a hydraulic die capable of adjust the thickness vertically and a semi-automatic light-control clamping unit. It is suitable for many materials, including PP PE etc. And our company can offer the relevant mould for your every need.

Specification:

Parameter | Unit | QJ80B | QJ90B | QJ100B | QJ120B |

Material | / | PP,PE etc | PP,PE etc | PP,PE etc | PP,PE etc |

Max. Product Volume | L | 30 | 60 | 120 | 160 |

Productive Capacity | pcs/hr | 120-200 | 150-200 | 200-280 | 200-360 |

Die Number | set | 1 | 1 | 1 | 1 |

Clamping force | KN | 210 | 360 | 500 | 760 |

platen opening stroke | mm | 250-700 | 400-1000 | 500-1400 | 700-1800 |

platen size | mm | 750*600 | 880*780 | 1020*1060 | 1300*1620 |

Max mould size | mm | 560*630 | 700*960 | 800*1260 | 1200*1700 |

Mould thickness | mm | 250-350 | 450-500 | 350-700 | 250-350 |

Accumulator capacity | L | 4.5 | 6.6 | 12 | 18 |

Heating Zone Number | Part | 7 | 7 | 7 | 7 |

Die diameter | mm | 300 | 350 | 450 | 600 |

Injection pressure | Mpa | 8 | 8 | 8 | 8 |

Screw diameter | mm | 80 | 90 | 100 | 120 |

Screw L/D ratio | L/D | 20:1 | 20:1 | 20:1 | 20:1 |

Plasticising Capacity | Kg/hr | 90 | 110 | 130 | 240 |

Screw rotation rate | r/min | 10-86 | 10-86 | 10-86 | 10-86 |

Voltage/ Frequency | V/ HZ | 220-380/50-60 | 220-380/50-60 | 220-380/50-60 | 220-380/50-60 |

Driving Power | KW | 50 | 75 | 90 | 130 |

Heating Power | KW | 35 | 45 | 60 | 80 |

Average Power | KW | 32 | 38 | 50 | 95 |

Compressed Air Required | Mpa | 0.7 | 0.7 | 0.7 | 0.7 |

Dimension | m | 3.82*1.4*2.6 | 4.4*1.8*2.7 | 5.4*2.5*3.8 | 7.0*3.5*4.8 |

Weight | Ton | 11.5 | 12.5 | 17 | 19 |

Note: Due to continual improvement, specifications are subject to change without notification. Please refer to the latest actual machine.We will even send an engineer to your country to help set up the machine.

PS: Our company specializes in the manufacture of bottle blowing machinesplastic injection molding machinesPET preform and plastic products. Just tell me what plastic product you want to produce and I will help you choose the best model for your needs. We believe that our competitive priceshigh quality and excellent service will bring us both benefits. Choose us-choose the best!

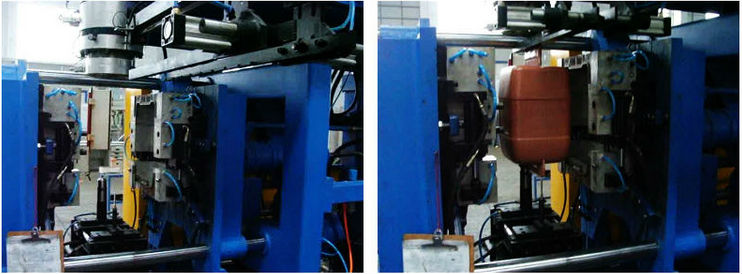

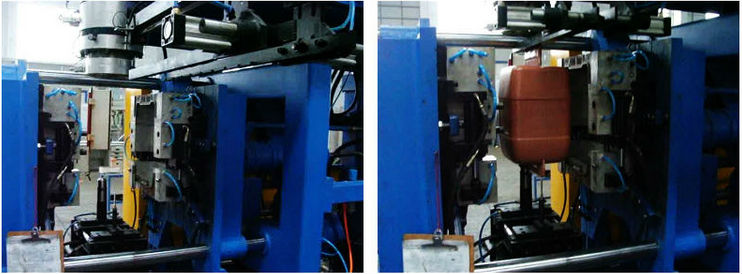

Detailed Images

Finished Products

Packaging & Shipping

Company Information

Our company specializes in the manufacture of QJ series universal Hollow auto-blowing machines, QJ Hollow Blow Molding machines, and the QJ series of plastic mould. The type QJ series adopt famous components. They can work normally under 30kg of pressure, and high yield in the finished products. The day yield attains 20000-72000 bottles, being applicable to (PET) bottle of mineral water, beverage, oil, medicine and polycarbonate (PC), polypropylene (PP), polyethylene (PE) and other heat-resistant packing products. Our company manufactures various plastic molds for the production of automobile parts, household appliances, and daily necessities.

Our Services

TRAINNING

The Buyer could dispatch their operators to the Seller’s factory for training, including machine operation, maintenance & simple repairs; Or against the requests of the Buyer, the Seller’s technician could train the Buyer’s operators in the Buyer’s factory in the periods of installing & adjusting; The training is free of charge.

INSTALLATION & ADJUSTMENT

The Seller could dispatch an engineer against the requests of the Buyer to install and adjust the machines for one week in the Buyer’s factory. The Buyer should make a reservation in advance before delivery of the machines; The Buyer should pay for the engineer’s visa application cost, round air tickets, food & board before his departure; And pay USD 80/day to engineer.