Product Description

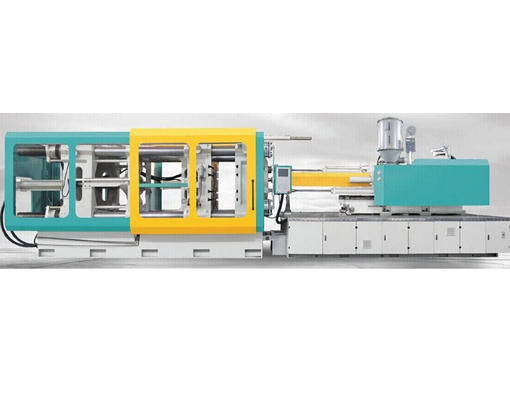

PET preform makingmachine

1.Siemens LCD control

2.Large opening stroke

3.usd for pet preform and cap

4.CE,SGS,ISO

PET preform making machine

Full Automatic PET Preform making Machine For Plastic bottle

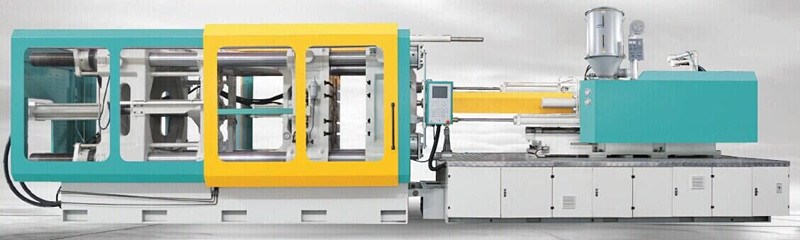

FUNCTIONS:

1) LCD computer control with big display screen

2) Hydraulic double proportional valve

3) Hard chrome plated high tensile strength steel tie bars

4) Generous space for fitting large moulds

5) Large opening stroke

6) Two position transducers to control Clamping and Injection

7) Four stages of injecting, independent velocity and pressure control

8) Hydraulic mould height adjustment device

9) Screw cold-start prevention device

10) Melt decompression control

11) Screw back pressure control

12) Multiple hydraulic ejection

13) Differential high speed clamping

14) Centralized lubrication system

15) Low pressure mould protection device

16) Mechanical safety interlock

17) Double electrical safety interlock

18) Oil return filter

19) Oil tank with inner stainless steel container

Detailed Images

Finished Products

Packaging & Shipping

Company Information

Our company specializes in the manufacture of QJ series universal Hollow auto-blowing machines, QJ Hollow Blow Molding machines, and the QJ series of plastic mould. The type QJ series adopt famous components. They can work normally under 30kg of pressure, and high yield in the finished products. The day yield attains 20000-72000 bottles, being applicable to (PET) bottle of mineral water, beverage, oil, medicine and polycarbonate (PC), polypropylene (PP), polyethylene (PE) and other heat-resistant packing products. Our company manufactures various plastic molds for the production of automobile parts, household appliances, and daily necessities.

Our Services

TRAINNING

The Buyer could dispatch their operators to the Seller’s factory for training, including machine operation, maintenance & simple repairs; Or against the requests of the Buyer, the Seller’s technician could train the Buyer’s operators in the Buyer’s factory in the periods of installing & adjusting; The training is free of charge.

INSTALLATION & ADJUSTMENT

The Seller could dispatch an engineer against the requests of the Buyer to install and adjust the machines for one week in the Buyer’s factory. The Buyer should make a reservation in advance before delivery of the machines; The Buyer should pay for the engineer’s visa application cost, round air tickets, food & board before his departure; And pay USD 80/day to engineer.