Mini Film blowing Machine

Feature

The machine take the HDPE or LDPE as raw material, through heating, extrusion, blowing, stretch, winder and final be roll thin film.The finished plastic thin film is widely used for supermarket bag,garbage bag,various plastic package bag, farmland film.cote film and compound thin film.

Main Technical Parameter

MODEL | SJ-45M |

SUITABLE RAW MATORIAL HDPE LDPE LLDPE |

Diameter of Screw | 45mm |

Reduced diameter of film | 100-600mm |

Single-face thickness of film | 0.01-0.10mm |

MAX.EXTRUSION OUTPUT(HD) | 40kg/hr |

MAX.EXTRUSION OUTPUT(LD) | 55 kg/hr |

SCREW L/D | 30:1 |

Power of main motor | 11kw |

Power of traction motor | 0.75kw |

Heating Power | 11kw |

Overall size | 2.6*1.9*3.5m |

Weight | 1.5T |

Pictures show

Vane

Winding part

Our Team And Customers

Certification

Installation&Training Service

Our Service

Welcome to visit our factory,bring you sample to test machine on the spot.

Manual provided in English and operation video provided.

Guarantee Service

We guarantee the machine in good quality for one year since the day we supply qualified debugging.

Debugging Service

We are in charge of install and debug the equipment for free,including arrange our technicians train you the operation in our company or client’s factory!

After Service

In order to ensure the equipment in normal operation,we would be in charge of the service of supply the maintenance and spare parts,which would be helpful to make the machine in best running situation.

Maintenance Service

We have a powerful technical service team,which can meet with any emergency maintenance;The warehouse have a large stock of all type spare parts,which can solve the clients’ emergency requirement of spare parts.

Whole Life Service

When the time guarantee service finish,we still willing supply the whole life service,the most reasonable price and complete spare parts to clients.

New products

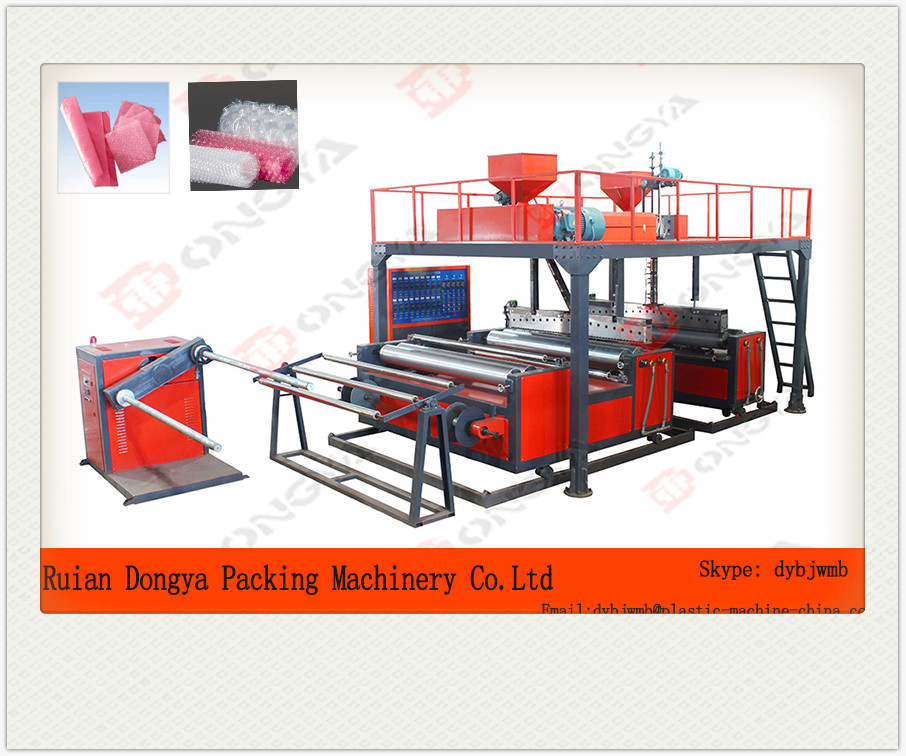

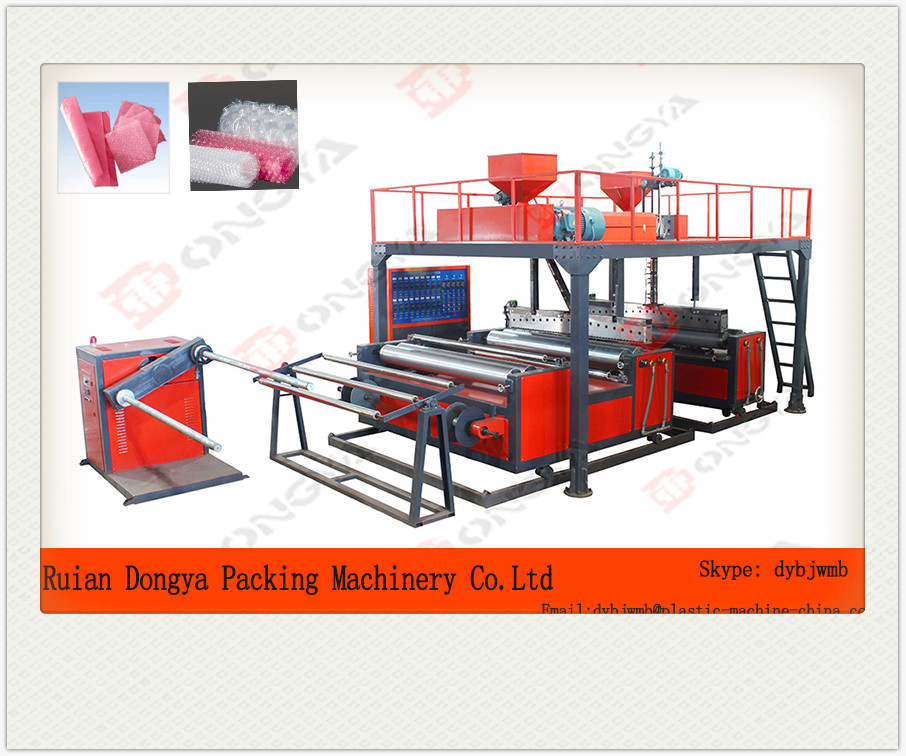

Bubble Film Machien

Bubble Film Machien

Blow Film Machine

Blow Film Machine

Stretch Film Machine