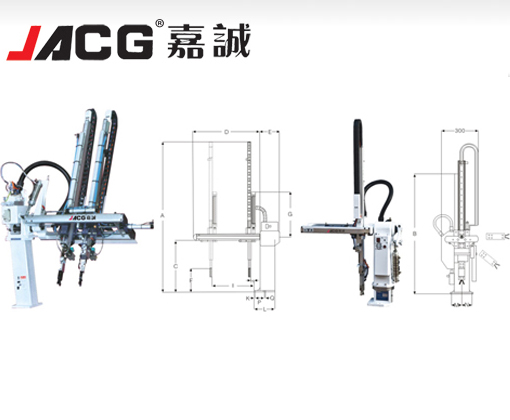

Swing-Arm Robots

Performance characteristic F series Swing Arm Robots are applicable to all types of horizontal injection machies 15-200T rof taking out the products and runners.The models are550/650.This model has single arm type and double arm tvpe.

Single arm type can be used for griping the products or runners while the double arm type can be used for griping both products and runners at the sme time.The gripper can spin the finished products with 90 degree angle. The molding machinese equip with this robot can help youimprove efficiency and quality,to ensure the safety for the operator,to reduce cost for worker,exactly to control the capacity and to reduce waste. The entire Robot adopts Aluminum alloy precision die-casting molding and matches CNC precision precision process which make a steady whole body can bear the high speed movement.The up and down srms all use the import high-rigidity linear slide.Crosswise Stroke uses Aluminum alloy extrusive beam with light weight and high-rigidity matching with linear bearing and high-rigidity bearing can satisfv the requirement of taking out the finished products quickly,steadily and with small shake and long service life. The arm adopts import high-rigidity linear slide and Aluminum alloy beam which has the steady activity and long service life. When changing the directions of product’s placement.only toadjust the screws and no need to replace the air pipe and Magetic reed switches. The Robot has the gripper which can spin 90° angle to place the finished products. When replacing the mould only to loosen the fixed handle to make the whole body to spin 90° angle to improve the improve the efficiency of mould replacement. Complete functional type of Robot reserves one set to suck the loop system.One gripper sucks the finished product while the other one sucks the runer.These two grippers or suckers can be used for taking ort the finished products of one mould for multi-cavity.

NOTE:Double ARM Lable(D)Double Seetion Lable(B) |