Details

◆ machine for the modular design, injection mold parts and a variety of stitching can be part of the portfolio, expand the selection range;

◆ two sets of independent parallel layout of the injection molded parts, according to the amount of product requirements of the radio customized plastic and more by their matching flexibility;

◆ screw, barrel of imported high-quality copper alloy by ion-nitriding treatment, resistant to corrosion, wear resistance and long service life advantages, and can be produced according to engineering plastics properties, matching special screw;

◆ two sets of injection components, can be injected at the same time to do action, forming a two-color products, greatly shorten the molding cycle;

◆ All components used in roll-type mold oblique row of five pivot toggle-type clamping structure, the various parameters optimized by the computer-specific software designs to be confirmed;

◆ two independent hydraulic top-out of the system can choose a variety of push-out method;

◆ Double-bit to 180 ℃, dynamic template turntable, using high-performance proportional valve controls the direction of hydraulic motor servo motor drives, switch-mode pressure, speed sub-control, to ensure the transfer-molded fast, stable and accurate.

◆ turntable rotation of imported high-performance, long life, can be axial movement of needle bearings, and in line with the fixed-bit pin and hydraulic pin co-located to ensure the turntable position to prepare to protect mold safety;

◆ turntable mold cooling water connections, dynamic simulation of cold water required can be easily connected from the turntable so as to avoid cold water pipe winding, interference;

◆ two separate sets of proportional pressure flow control oil line, used to control driving two sets of injection parts and two sets of hydraulic top-out system;

◆ two injections, two sets of push-out and switching mode are controlled electronically foot travel;

◆ excellent hydraulic system designed to meet the world famous the control valve and pump, so that the whole control of the machine to achieve the best state;

◆ Two-color injection molding machine dedicated computer, with large-screen LCD color LCD screen and dedicated user interface, has a good performance of human-computer interaction;

◆ Double / double product once a shape, make the product significantly reduced the degree of contraction, greatly improving product appearance, so as to enhance value-added products;

◆ products once molding, eliminating the need for assembly or insert molding placed on processes, shorten production cycles, improve production efficiency;

◆ unique rotary dynamic model designed to allow a two-tone color mold products and can also use the two sets of common mold (mold thickness the same as) the same time, the production of two different systems work

| 1, turntable rotation no contact with the die wall and reduce wear caused by the failure to do in the open mold prior to confirm precise wheel location in order to protect the safety mold |

|---|

|  |

|---|

| 2, injection part of the material has two independent control groups, synchronous movements do injection, two-color molding time can be shortened mate forming the same period, increasing operating margins. |

|---|

|  |

|---|

| 3, Double to 1800 , dynamic template turntable, using high-performance proportional valve controls the direction of hydraulic motor servo motor drives, switch-mode pressure, speed sub-control, to ensure the transfer-molded fast, stable and accurate. |

|---|

|  |

|---|

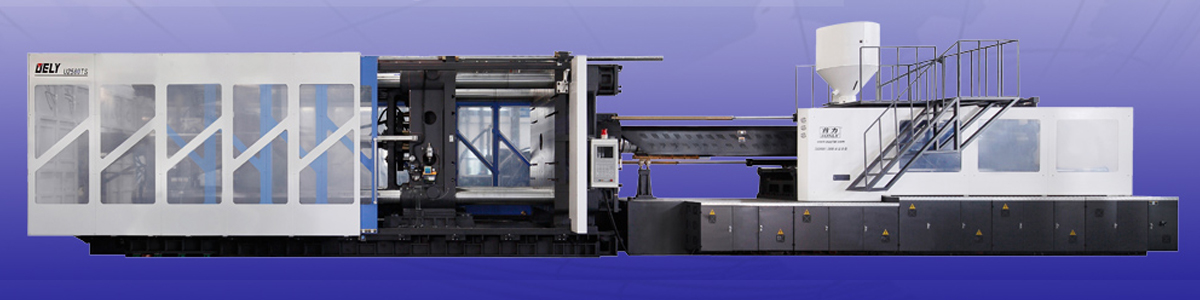

| JCSS Series Rotary clear at all levels, two-color machine, that contains two sets of parallel arrangement of the injection components, and with a hydraulic motor or a servo motor-driven rotating the template device (wheel) |

|---|

|

|---|

| The first injection molding machine plastic injection molding, open mold after the turntable to rotate the entire dynamic model, together with the workpiece 1800, after the alignment cavity mold for a second injection for a total of plastic molding; the first plastic injection and the second plastic injections are carried out concurrently. The second injection molding cycle, reverse-1800 turntable rotation. |

|---|

|

|---|

|

|---|

|

|---|

| ITEM / MODER | UNIT | Parameters |

|---|

| Injection A (variable pump) | Injection B (single pump) |

| A | B | A | B |

| Screw Diameter | MM | 30 | 35 | 32 | 38 |

|---|

| Shot Volume | cm3 | 113 | 154 | 128 | 181 |

|---|

| Shot Weight(PS | g | 100 | 138 | 115 | 162 |

|---|

| Injection Pressure | Mpa | 230 | 170 | 203 | 145 |

|---|

| Screw Speed | g/s | 89 | 121 | 86 | 122 |

|---|

| Plasticizing capacity | g/s | 8.3 | 11.58 | 9.6 | 13.4 |

|---|

| Screw speed | rpm | 300 | 250 |

|---|

| Clamping Stroke | KN | 1680 |

|---|

| Platen Stroke | mm | 420 |

|---|

| THICFNESS | mm | 120-500 |

|---|

| Space Between Tie-Bars | mm | 700x400 |

|---|

| Ejector Stoke Distance | mm | 130 |

|---|

| Root out the number of pole | 根 |

|

|---|

| EJECTOR FORCE | KN | 246 |

|---|

| Die plate size | mm | 926x666 |

|---|

| Wheel diameter | mm | 800 |

|---|

| Dual-center distance | mm | 420 |

|---|

| Die minimum spacing | mm | 70 |

|---|

| Pump Maximum Pressure | KPA | 14 |

|---|

| Electric Motor Power | kw | 22 |

|---|

| Heater Power | kw | 6x2 |

|---|

| Machine Dimenshion(LxWxH) | m | 5.2x1.35x1.9 |

|---|

| Machine Weight | t | 8 |

|---|