YCB rubber injection molding machine series

I. Features:

YCB rubber injection molding machine has a simple structure, high pressure, high efficiency.

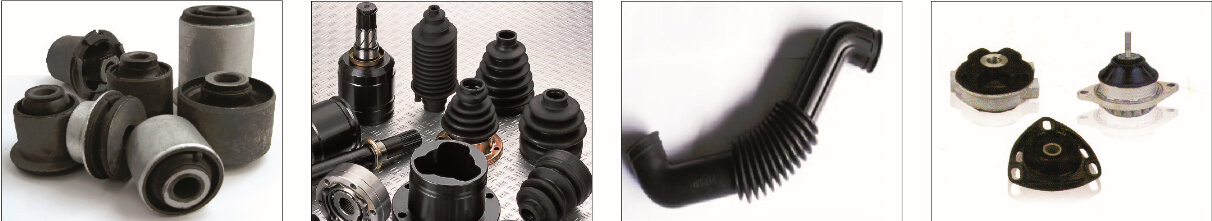

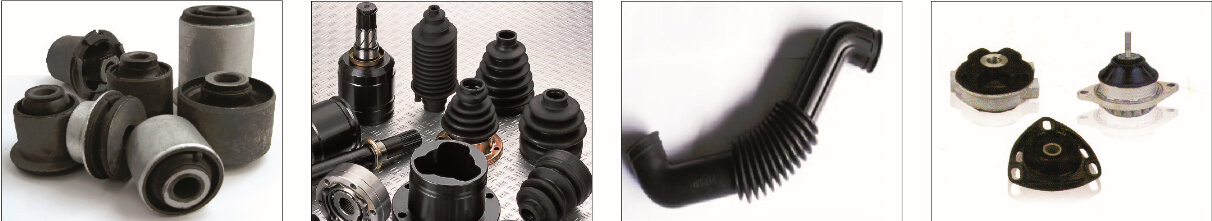

Second, use:

YCB rubber injection molding machine is suitable for all kinds of rubber, bakelite, thin metal, building materials and other pressing; This equipment is mainly suitable for the production of metal inserts, complex shape, thick-walled, auto parts, and other complex process large cross section, forming more difficult rubber model products, products with a dense and precise geometry, flash less.

Third, the structural characteristics:

1 master cylinder mold first, then by the injection cylinder plastic material into the mold cavity uniform, dense tissue products, accurate geometry, flying edge is less;

(2) Imported touch screen LCD, manual and automatic switch freely; simple operation, high accuracy;

3 Quick opening and closing mold, high production efficiency; slow locking to protect the mold;

4 selection of imported dual proportioning valve, advanced and reasonable configuration, save energy;

5 automatic mold, automatic flap, reduce labor intensity;

Fourth, the action process:

Initial state reset program starts ejector cylinder mold clamping clamps slowly moved rapidly, pressure will be put into the cylinder exhaust rubber, vulcanizing mold mold out of the top of the tank work, separation mold and removing products

2RT:

The first layer of the initial state of M1 fell into place the template moved into place fast mold clamps slowly, pressing the plastic material into the cylinder exhaust, vulcanization mold to mold the displacement of the first layer in place M1 rose to open the top place out products

3RT:

Initial state fell into place the second layer M2 M1 fell into place the first layer of the template moved into place fast mold clamps slowly, pressing the plastic material into the cylinder exhaust, vulcanization mold to mold the displacement of the first layer in place M1 rose place the second layer M2 increased by stripping out the product in place

4RT:

Initial state closed down the second layer M2 M3 rose template template with the third layer pallet out of the shift mode M2 M1 second layer of the first layer drop down into place the template in place quickly moved into place slowly locking clamping, pressing the plastic material exhaust into the barrel, vulcanization mold to mold the displacement of the first layer in place up in place M1 M2 M3 release second layer up in place with the third layer template template shift care into M2 declined positioned under the second layer template finalized after rising, make products out, remove the product, clean the mold.

V. Technical parameters:

Model | LD-YCB200T |

Tonnage | 200T |

Clamping force | 2000KN |

Maximum system pressure | 21Mpa |

Clamping stroke | 300mm |

Rapid clamping speed | ≥60mm/s |

Heating plate size | 600mmx550mm |

Heatingplate spaceing | 450mm |

Max temperature | 250℃ |

Barrel specifications | / |

Plastic injection pressure | 60Mpa |

Injection stroke | 380mm |

Max ejector force | 60KN |

Ejector stroke | 250mm |

Optional | 4RT |

Motor power | 7.5KW |

Heating power | 18.3KW |

Machine size | 2000mmx2200mmx3300mm |

Weight | 4500kg |

Oil tank capacity | 400L |