JC-XLB series self-propelled mode for multi-layer or more layers of vulcanizing mold. Mainly for the production of automobile parts, rubber shock pad, etc., especially for production of metal inserts, complex shape, thick-walled, large cross-section and so on. Can also be used for other thermosetting plastics, sheet metal and all kinds of rubber products, bakelite products, handicrafts and building materials and other pressing;

Second, the structural characteristics and functions:

● The machine is precision poster under the roof structure, the host from the upper beam, lower base, moving platform, cylinder group and the columns and other components. Piston cylinder group structure, mounted on the lower plane seat.

● The device has independent power sector and electrical systems, electrical boxes fastened to the right of the host, centralized control buttons, working pressure, heating temperature, gas discharge time, residence time, gas discharge times, curing time, clamping pressure can be set, easy to operate.

● This model has two working modes manual and semi-automatic.

● The machine is single structure (also according to the user needs to select dual or multiple machines), with the traditional dual-motor dual-pump compared scientifically designed, compact, low noise; pump is located in the right side of the host, the fuel tank is located behind the electrical box; hydraulic and electrical systems have overload protection device, safe and reliable.

● machine work, the upward movement of the plunger from the bottom mold, molding, and automatic heat, pressure and exhaust functions, to ensure product quality.

● the use of international segmentation heating technology, high precision temperature control and energy-saving products vulcanizing, pump motor to stop working.

● With automatic pressure compensation function, in the rubber pressing process, due to the flow of raw materials caused by the pressure drop can be obtained automatically added.

● With automatic temperature control system, advance warm, eliminating the need to wait to go to work will be able to produce products heating time and improve production.

● Seals imported from Japan NOK, hydraulic cylinder uses technology imported from Germany, reliable sealing, long life.

● The United States imports proportional control valve, pressure and flow are free to set up, configure advanced and reasonable, reduce energy consumption.

Third, the action process:

2RT:

The initial state into a mold compound M1 fell into place the first layer of the template moved into place fast mold clamps slowly, exhaust pressure, vulcanizing mold to mold the displacement of the first layer of M1 in place to open up the top place out products

3RT:

The initial state into a mold rubber fell into place the second layer M2 M1 fell into place the first layer of the template moved into place fast mold clamps slowly, exhaust pressure, vulcanizing mold to mold the displacement of the first layer in place M1 place the second layer M2 rose up stripping out the product in place

4RT:

Initial state closed down the second layer M2 M3 rose template template with the third layer will move out of the mold pallet mold plastic material into the second layer M2 M1 fell into place the template in place the first layer down shift lock in place fast mold Slow tight, pressurized exhaust, vulcanizing mold mold a place to shift up in place the first layer M1 M2 M3 release second layer up in place with the third layer template template shift care into the second layer template M2 fell after rising positioned under clappers make products out, remove the product, clean the mold.

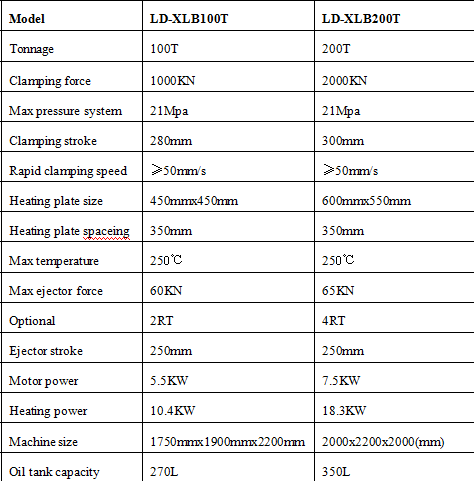

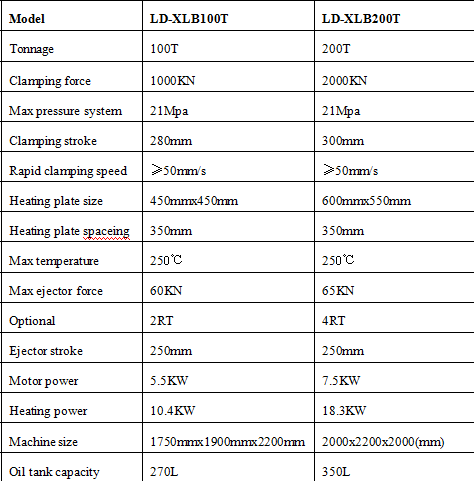

Fourth, the technical parameters:

NOTE: Specifications are subject to change without notice.

Fourth, after-sales service:

Quality products, preferential prices, quality service to your preferred!

Companies around the customer-centric, before you purchase, we will provide you plan, design the best process solution. Purchase, will be free to assign a dedicated service personnel arrived at the scene for your installation, to help you plan and manage equipment, to customer satisfaction.

1.24 hours service models, such as the products have any problem, Ningbo Ji-chang company will deal with the problem in the first time, providing customers with fast, attentive, quality of service, the downtime to a minimum. (The parts in question are Ningbo Ji-chang company has incurred liability Ningbo Ji Chang, is a customer responsibility borne by the customer)

(2) Quality guarantee period from the commissioning date of the end of the year free warranty, the customer under normal use damage occurs by the Ningbo Ji-chang company for the first time given free replacement.

3 product life-long maintenance, non-failure warranty period, Ningbo Ji Chang-home services for the company given the need to replace parts, and only pay its cost.

4 If the company due to customer without the consent of Ningbo Ji-chang to transform the machine, or ask someone to repair or replacement as a result of failure is not in terms of quality and product lifetime warranty service area.

5. Ningbo Ji-chang companies will regularly visit customers, understand customer's comments and improvement direction, solve customers in the normal use of the machine in the process of the difficulties and problems encountered.