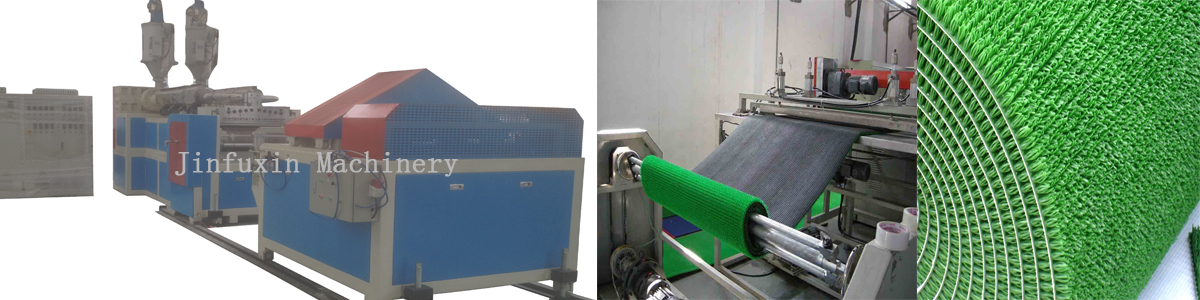

PET Strap Production Line

Description

With 100% bottle flakes recycled material, to produce various specifications of PET strap. It consists of dehumidifying and crystallizing system, extruder, screen changer, mould, oven, haul-off, and winder, etc.

Why choose us:

1. Can use 100% recycled bottle flakes material

2. The final straps can be packed automatically

3. We major in Pet Strap Production Line for 15 years

4. Always have at least 3 sets of sample machine in our workshop

5. Can take customers to see the running machines

6. Can test the machine for customers

Introduction

Power supply | 380V,3 phase,50HZ |

Raw material | PET granules or PET recycled material |

Width of final product | 9-25mm |

thickness of final product | 0.5-1.5mm |

Max Capacity | 70-350kg/hour |

Manpower | 2-4 persons/shift |

Machine Dimension | 35-55*5*5m |

BRANDS |

Motor | Qingdao Red Flag (Founded in 1976) |

Gearbox | Jiangsu Jiangyin (specialize in gearbox) |

Contactor: | Siemens |

Temperature controller | Omron |

Inverter | ABB |

Different Models

Model | Strap Qty | Output |

SJ-75/33 | 1 | 70kg/h |

SJ-90/33 | 2 | 120kg/h |

SJ-120/33 | 6-8 | 250kg/h |

SJ-130/33 | 8-16 | 330kg/h |

Best Services

1. The guarantee period is 1 year and service is available lifelong.

2. Our expert will answer any inquiry within 24-48 hours and it will be solved as soon as possible.

3. Our company supplies the complete technical support documents and the relative drawings of the electric components written in Chinese and English.

4. Our company shall send enough technicians to the Buyer’s company for installation, debugging, training and technology transfer till customers can operate independently and manufactures eligible product.

Plastic Strap Making Machine/ Pet Strap Production Line/ Pet Strap Machine/ Pet Strap Making Machine/ Belt Strapping Machine/ Plastic Packing Belt Machine