wpc wall cladding machine

Wood plastic machine, WPC machine

WPC decking machine for flooring

wood plastic composite machine

WPC profile extrusion line

WPC wall panel production line

Video for WPC machine running:

https://www.youtube.com/watch?v=2m-jwhF_uZQ&list=PLXb0odcPrJgg6n2qfV6GP0jWJwLoisVIC

we have rich experience in making wpc machine, we have installed WPC turnkey project in Many countries, such as Romania, Australia, Uzbekistan, India, Malaysia, Ecuador, Lebanon, Russian, Turkey, Saudi arabia, China, Tunisia, Oman, Indonesia,Mexico,Poland, Egypt,Qatar ...

WPCs combine the advantages of wood with the processability of plastics They can be sawn, nailed, screwed and worked like wood, yet also extruded and moulded like plastics; they offer greater durability and moisture resistance than softwood. They can also replace exotic tropical hardwoods.

Description for wpc machine:

| Raw material | PP/PE/PVC+waste wood/rice husk |

| Final product | Decking, garden railing, garden furniture, pallet, outdoor wall cladding.... window and doors, ceiling panle, wall siding panel, flooring, furniture board |

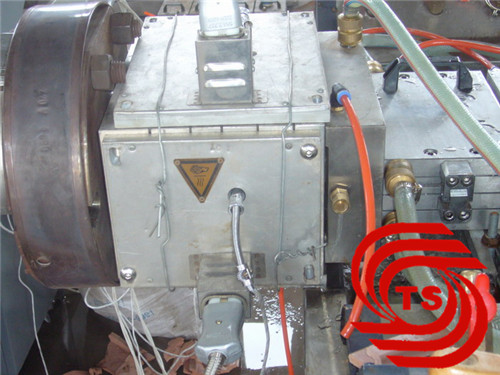

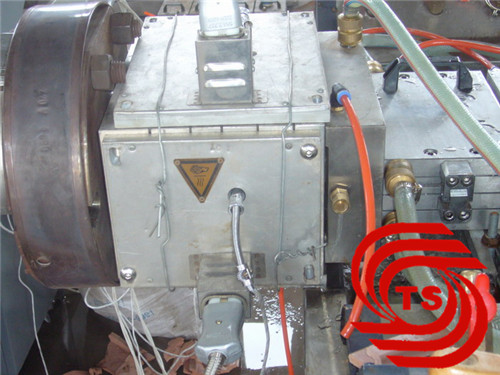

| Process: | Milling →Mixing → Granulating → Extruding → Mold → Product → Calibrating → Hauling off→ Cutting off→ Embossing or polishing→ Final product |

Features for wpc machine:

1)This technology is suitable to produce WPC products at high value with variety of plastic and nature fiber,and the material is 90% of waste plastic and waste natural fiber. 2)With scientific and reasonable technology,the machine has high efficiency and runs stably 3)The parallel twin screw extruder is used to mix the wood and plastic,and get good homogeneous melt. 4)This is one step WPC extrusion technology,which saves energy 5)This production line can produce wpc products of different specifications only to change mold. 6)Imported PLC automatic control. |